ABSTRACT

It is explained that the new ISO55000 series of standards for the management of physical assets, based on the earlier PAS 55 specification developed by the IAM, are not about managing assets, but about delivering business value. The ISO 55000 framework ― a set of three standards covering terms and definitions, requirements and guidance ― does not address the reduction of risk, so to deliver maximum value from physical assets it needs to be combined with the ISO31000 Risk Management framework alongside the concept of Reliability Leadership. In this context, risk management, value-driven decision making, and the need for managerial ‘lines of sight’ to the asset base are discussed, and a framework for managing asset reliability performance proposed. The importance of the Certified Reliability Leader is emphasized.

[This paper is based on a webcast presentation, with the same title, made to the Tivoli User Community.]

INTRODUCTION

In 2002-2004 the Institute of Asset Management (IAM), in conjunction with the British Standards Institution (BSI) developed PAS 55, the first ‘Publicly Available Specification’ for optimized management of physical assets. This has become an international bestseller, with widespread adoption in utilities, transport, mining, process and manufacturing industries worldwide.

The 2008 update (PAS 55:2008) was developed by fifty organizations from fifteen industry sectors in ten countries. The International Standards Organization (ISO) then accepted PAS 55 as the basis for development of the new ISO 55000 series of international standards. Because of the standards’ 100% focus on business value, they are now being adopted by more and more businesses and, in fact, companies with poor asset management practices may well have problems getting risk cover from their insurance provider.

UNDERSTANDING ASSET MANAGEMENT

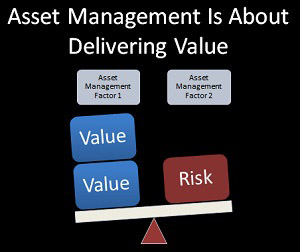

Asset management is not about managing assets. According to ISO 55000 an asset is a ‘thing, an item or an entity that has actual or potential value’. This might expand your thinking beyond physical assets to include your computerized data or your maintenance technicians and their knowledge and so on. ISO 55000 questions whether you are managing all of these as you would a physical asset, and sees asset management as a coordinated set of activities to realize all the value of all assets. So, to use a paradox, asset management is not about managing assets, but about delivering real business value. Organizations deliver that by aligning everyone’s understanding of value and understanding of risk, and balancing that to the profile that’s been set (see Figure 1).

This global demand for asset performance is outpacing available capacity and infrastructure. Organizations have aging systems, and old and traditional business practices, and these limit the tangible responses available to address this problem. As well as the major problems resulting from an aging asset-base, there is also a lack of understanding about risk. There is increased demand, increased standards or growing expectations from existing assets; the expectation of what organizations will deliver is going up almost on a daily basis.

Whether you are in a public or a private organization you are facing increased scrutiny whilst technological obsolescence is arriving more rapidly and businesses struggle to keep up with the latest advances. Financial constraints are huge; capital tends to flee from where there’s a lot of risk and instead goes to places where there’s not so much risk. An aging workforce and a skill shortage combine to create even greater challenges. The growing realization is that these issues can be addressed through the best in asset management practices.

THE ASSET VALUE RECIPE – THE IMPORTANCE OF RISK

As explained, the BSI’s PAS 55 Asset Management standard paved the way for ISO 55000, but here it lost an important element, Risk Management. For what are seen as political and procedural reasons, risk was not covered in the ISO 55000 series of standards. But without a robust risk management process your organization is likely to miss the potential value available from a more comprehensive or holistic, way of looking at assets. So, in addition to ISO 55000, you need a framework for reliability to reduce your risk. Without it, your assets can struggle to perform and your machinery may actually punish you for mistreatment and that usually happens at the most inopportune time.

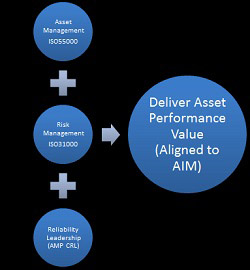

The asset value ‘recipe’ to deliver maximum value from physical assets is to combine the ISO 55000 Asset Management framework and the ISO 31000 Risk Management framework alongside the concept of Reliability Leadership. The Association for Maintenance Professionals expresses the framework for this in the role they promote of a Certified Reliability Leader (AMP CRL). Through this they seek to combine the delivery of asset performance value that is aligned to the organization’s ‘AIM’ (see Figure 2 – and more on AMP CRL later).

The AIM, which relates to organizational objectives, is defined as a system. Executive management creates the AIM for the system, which also could be referred to a strategic plan. It is a requirement of ISO 55001 that everyone understands, and is able to articulate, the AIM.

ISO 55000 IN MORE DETAIL

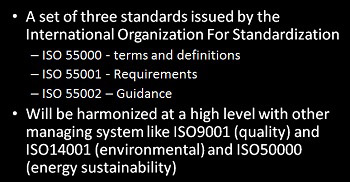

ISO 55000 is a set of three standards or documents, issued by the International Organization for Standardization, which covers the terms and definitions around asset management. ISO 55001 lays out the requirements for an Asset Management system and ISO 55002 provides guidance for implementing ISO 55001.

If your organization already follows ISO 9001 for quality management or ISO 14001 for environmental management or ISO 50000 for energy sustainability, you already have the managing system framework for ISO 55001. ISO is now looking to harmonize these standards at a high level (See Figure 3).

ISO 55000 sets the definitions, the terms and requirements for the managing system framework and the guidance, but it doesn’t tell an organization how to perform asset management or how to deliver value and reduce risk. In fact, it specifically excludes technical standards and guidance. Value from your assets is seen as being delivered by the decisions and processes that are made in managing the risk opportunities around acquiring, operating, maintaining and decommissioning your assets.

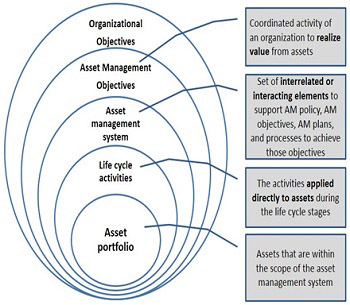

As illustrated in Figure 4, asset management objectives are a coordinated set of activities that help your organization realize the amount of value delivered from the assets. They are subdivided into interacting elements that allow the organization to achieve those objectives.

RISKS AND DECISIONS

Understanding risk

Every organization must have a formal understanding of risk in order to make good decisions. Organizations of all types and sizes face internal and external factors and influences that make it uncertain whether they will achieve their objectives or not; risk is the effect this uncertainty has on an organizational objective.

All activities of an organization involve risk and this is managed by really understanding it, identifying it, analyzing it and then evaluating whether the level of risk should be modified by a risk treatment in order to satisfy agreed risk criteria (see Figure 5). This is the standardized process required by ISO 31000 (or your organization may have its own process for managing risk).

Decisions drive value

Asset management, together with risk management, allows asset owners to scale and apply solutions that are appropriate for the asset challenges that they are facing. To make improvements and improve value they must have the most effective of decision-making tools to ascertain whether an action such as maintenance or renewal is the best option.

Decision support, especially using good information management techniques, allows you to make the least bad sacrifice, or to suffer the least from what you choose not to do, because everyone has to work in constrained environments. If you create decision criteria on how much to spend, and when to spend it, that is asset management. You need to make effective and efficient decisions to drive value.

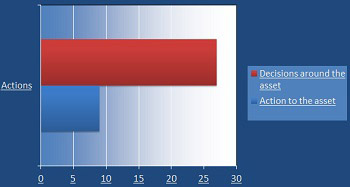

As shown in Figure 6, a study was made of the decisions around driving value from assets. Only 9 of those decisions were related to actions taken directly on an asset; 27 were made around or about an asset. Examples include operator motivation or maintainer training, decisions about operating load or duty cycle. These make a huge difference to the value derived from an asset. Decisions to in-source or outsource certain functions are not things you do to an asset, those are things you do around an asset.

Research has suggested that only 25% of the decisions made to drive value from an asset are related to actions performed directly on that asset; culture is often the biggest single challenge in implementing asset management. It is leadership that creates culture and it is leaders who make decisions. On that basis, leadership is one of the most important elements that you have to focus on in asset management and leadership is now a key aspect of the new Asset Management standard ISO 55001.

Regardless of how good your reliability strategy is, it is your organizational culture that delivers its performance. Culture is built from within and leaders ― who aim at engaging employees and team members in delivering reliability and asset performance for the organization ― cultivate it.

CONNECT TOP MANAGEMENT DECISIONS TO THE ASSET BASE

So what you can learn from this is the importance of connecting top management to the asset base and how the ISO 55000 standard provides for this. This is achieved through an Asset Management Strategy, an Asset Management Policy and an Asset Management Plan and these are written documents designed to be used within a reliability leadership culture. This is very significant because, in your organization, top management may already think they have all the aspects of asset management, but, as defined by ISO 55001, it is a very rare organization that truly is driven by strategy, policy and plan for delivering value from their assets.

The organizational objectives are the real reason the organization is in business and these are typically focused on providing the maximum return on the stakeholder’s investment and are derived from the corporate business plan. On that basis, it is very important that you align your asset management activities to the aim of the organization.

ISO 55000 requires a ‘line of sight’ connecting the company’s asset-related policies and objectives to accomplishing the company’s organizational objectives. Line of sight means they can connect it directly, they can explain what their plans and activities are as directly related to the main organizational objectives.

As indicated in Figure 7 asset management can be used as an opportunity for this line of sight to force vertical thinking about optimizing value delivery from the assets in your organization. Assets are not just about running efficiently or running effectively, they are about delivering business value, and some assets are more important than others in that regard.

Top Management in your organization defines what value is and what risk is. Operational excellence at the Asset Management level means assuring that value can be delivered through the asset portfolio that is deployed. Reliability leadership assures that those assets will deliver their intended function in alignment with that value delivery ― and at Asset Care or Maintenance level that is about assuring the delivery of the capacity from those assets.

Align functional silos

As well as the top-down view of line of sight, asset management can also be used to align and force lateral thinking across your organization. Typically, organizations experience conflict between operations and maintenance, sub-optimizing performance metrics. They forget that human resources, for example, are a very important part of the asset management value delivery chain; poor staff retention means loss of knowledge, which means loss of an asset.

Purchasing and supply chain are also extremely critical as is Finance. The advantage of having a strategy, policy and plan as defined by Top Management in regards to Asset Management allows for all of these functional silos (see Figure 8) to be aligned for value.

The thing that all asset management programmes have in common is that they are about making the best possible decisions. You do that through Reliability enabling Asset Management decisions, on the one hand, and Asset Management decisions enabling Reliability decisions on the other. It is vital that this fundamental concept is understood.

RELIABILITY IN DETAIL

Where change succeeds

Many research studies indicate that approximately 70% of change efforts and new strategies fail to create a sustainable result, even though most of the strategies and techniques of Asset Management and Maintenance Reliability have been well known for more than thirty years. The need is for organizations to better understand the root causes of the high failure rate of ‘technical-only’ implementations and, in doing this, they must realize that it is very important not to view ISO 55000 as purely a technical implementation.

The Reliabilityweb.com approach

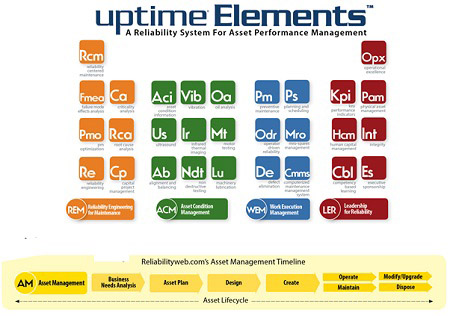

Uptime Elements (as illustrated in Figure 9) provides a simple way to understand a holistic, system-based approach to embedding reliability into an organization’s practices and culture. By using a unified theory to explain the fundamental elements of reliability and how they relate to each other, it allows everyone to gain an understanding of reliability appropriate to the work they do. There are four knowledge domains with an overarching asset management timeline, viz. ―

(i) Reliability Engineering for Maintenance – REM

The essence of this quadrant of the framework is about understanding what is critical in the delivery of the AIM of the organization, i.e. the business objectives. There is a need to undertake criticality analysis and this has to be loaded into your management software. There is a need to understand what assets are critical in the delivery of business objectives, since all organizations have constraints and do not have unlimited labour and unlimited budgets.

Efforts should be focused on those critical assets that are delivering the organizational value. That needs to be loaded initially, and then updated continually, into your management system. Once you understand which assets are critical, then you have a way of understanding how things can fail and can use techniques such as Reliability Centred Maintenance (RCM) or Failure Modes and Effects Analysis (FMEA) to understand the failure causes ―which have to match totally (or very closely) with what is in your management system’s failure causes. You capture failure codes in your software so that your reliability engineers can use that data to minimize future failures in your assets and improve capital projects.

(ii) Asset Condition Management – ACM

Once they understand what is critical in the way they fail, organizations can start to use tools such as predictive analytics and advanced condition monitoring. These are not just being applied on a random basis; there is a need to apply them to the most critical assets and to address the failure mode. In this way they can identify and formalize the failure analysis.

(iii) Work Execution Management – WEM

This is where organizations would tend to focus on computerized management systems. The quandary is that they can have efficient Work Execution Management, but if they are not focused on value-added work that is actually reducing asset failure they get very efficient at doing the wrong work or doing work that is not adding value. Organizations can be in a better position if they use things like preventive maintenance (PM) and make sure they have the right spare parts and consumables available. A Computerized Maintenance Management System (CMMS) or Enterprise Asset Management (EAM) system captures maintenance work, parts usage and, more importantly, failure causes so that the business can loop that back around to the reliability engineering to continually improve its approach to maintenance and reliability.

(iv) Leadership for Reliability (LER)

As already identified, in ISO 55000 leadership is the glue that holds it all together; managing the system and having the measures, the right people with the right competencies, working with strategy, policy and plan, with the right executive sponsorship to achieve operational excellence. This part of the framework is all about ensuring value delivery from assets.

The asset management timeline

There is a fundamental need to apply all four of the above knowledge domains to every aspect of the asset life cycle. Organizations tend to apply their efforts to the operate/maintain phase when they should be applying it at the business needs level, the asset planning level, the design level, the create level and the modify/upgrade level. This is the power of the asset management systems in ensuring the right decisions are made for value delivery across the entire asset life cycle.

THE BEST WAY FORWARD

Bridge the Capex and Opex gap

During capital projects is when you should be managing asset lifecycle value for the future operate and maintain phases, bridging the value believed to be between the Capex and Opex phases. Organizations need to spend a little bit more time, energy and effort to get the asset information right and to recognize the impact of future maintenance. More time is required for managing asset information at the beginning of a project, so that maintenance plans can be loaded and all spares are going to be in place. Once the reliability and maintainability is ensured this will pay big dividends during the operate and maintain phase of the lifecycle.

Truly recognize the importance of leadership

Within ISO 55000 a leader is anyone who helps another person, machine or gadget do a better job, meaning that there is leadership at every level of your organization. It doesn’t mean only the CEO or Reliability guru or computer system analyst; there is a need to engage everyone in the organization as a leader.

Organizations need a ‘roadmap’ to create the future and for this they need to make a declaration, to work with commitment, act with integrity and then actualize it by taking action.

Understand the asset management and operational excellence connections

This can be likened to the same principles as those of the Capex– Opex bridge. Organizations need to understand how value is delivered and how to address problems or ‘repairs’ when value is below expectations at every phase of the asset lifecycle. That is about connecting asset management with operational excellence to maximize business value.

Recognize the breadth of the impact

Of course there are the economic reasons for doing asset management, but it also enables environmental sustainability and social responsibility. When considering your organization’s environmental promises asset management can truly enable achieving these as well as your intentions for social responsibility. You can use asset management to bring together these three aspects of your corporate strategy (you can consider them as ‘people, planet and profit’ and do that regardless of what the economic situations are. Aligning the organizational objectives of environmental stewardship, social responsibility and economic prosperity can be achieved through effective asset management.

Understand the value of a Certified Reliability Leader

A recent initiative related to leadership, reliability and maintenance engineering saw the Association for Maintenance Professionals and the author get together to establish a ‘Certified Reliability Leader’ qualification and associated body of knowledge ― the previously mentioned ‘AMP CRL’. The first of three values of this is that a CRL understands the needs to be able to communicate about asset management and reliability at all levels, from explaining it to the CEO or to the newest junior recruit. the Uptime Elements framework enables this to happen. The second value is the assistance given in ensuring full acceptance that asset management is a never-ending journey. There is no final destination to reach, since the goal is always constant improvement, no matter what level you have so far reached. The third value is about recognition of community, both internal and external. Inside the organization it is about ensuring that there are empowered leaders and empowered people delivering the results for the organization. On the outside, it is about being highly active in the external community. The Tivoli User Committee exemplifies such an external community, where you meet peers who face the same challenges that you do and share what you did to overcome those challenges and inspire each other.

Take a consistent facilitated approach

ISO 55000 and ISO 31000 offer such an approach to making reliable asset decisions that balance risk and opportunity ― for your acquisition decisions, your operate and maintain decisions and your end-of-life decisions. It is about this that you will be audited, to ensure you are compliant with these standards, and for this you need software (your asset information system), to test, to capture and to refine those decisions. Finally, you need the leadership to take the people on this journey.

Remember where to begin

All that has been discussed creates some major challenges, when many organizations have perhaps thousands of assets. The answer is not to try and do everything at once, and starts with your critical assets, not all of your assets. Begin with a pilot opportunity and gain validity with this approach. ISO 55001 allows you to create an asset management ecosystem on one asset system, you do not have to attend to your entire company. This will allow use of the lessons learned as the next asset is chosen; that is how you’re going to make progress.

APPENDIX

Transcript of discussion following presentation to the Tivoli User Committee

Q: Would you agree that anyone who helps is a leader? Could you call people a helper?

T O’H: I respectfully disagree that a helper is another definition of a leader. Our definition of a leader is anyone who helps another person, another machine or a gadget. In this case possibly, you could view it as the computer technician that helps your asset management system do a better job; that should be still be considered a leader. Human leaders have to understand the landscape and the framework of asset management and how it fits into delivering business goals to enable and engage them. In a plant there are people who are not leaders by title but they’re going around the plant all day ensuring that other people are doing their jobs better, that the machinery they work around is functioning properly, as are their gadgets. That’s what I call a leader. You can call them a helper if you want, but I think it’s very useful to identify them as leaders.

Q. I would like more clarity on the term AIM. I don’t think that you mean asset integrity management, which is what we are most familiar with for that acronym.

T O’H: AIM, for us is ‘organizational objective’ and we use the word as defined by W. Edwards Deming in his book Out of Crisis.

Q: What has been the experience of Maximo clients about adoption of Asset Management standards?

Mary Bunzel: I would have to say that the adoption of the standards very closely matches the poll conducted today. The number of companies who are actually certified would be in the 7 to 10% range and more than 50% of the customers I speak with are, in fact, pursuing strategies that are ISO 55000 related. So, for example, if they are not yet fully certified, they may be working on the critical assessment aspect of it, looking at the risk of the failure of the asset, for example. Another might be working on refining work procedures to conform to stated corporate standards. The poll was very reflective of the status of various organizations around the world, although it is a bit different regionally. I would have to say that North America is on the lower end of the scale in terms of those adopting or in progress, whereas companies in Europe tend to be a little bit ahead. So, overall, I think it’s an important standard to pay attention to and if you’re not, you’ll find out shortly that others are watching that as well.

Eric Luyer: In the UK you see a growing number of companies in infrastructure, transportation ― but also energy, utilities, and oil and gas ― adopting PAS 55 and they are also interested in ISO 55000.

Q: Do you see the pace of adoption changing?

T O’H: Yes, it’s rapidly changing, and as Mary said, there might be some people that are not necessarily aiming at certification at the moment, but they’re trying to put the managing framework, and the procedures, and the processes, and the plans and the strategies in place, so they’re working behind the scenes to build the programme. Our numbers are showing literally thousands of companies moving towards at least compliance, if not certification, within the next four years, adopting this as a standardized business process because it’s so value-oriented. In the past, standards have been disparaged because they were not focused on value, they were focused on compliance; this standard has 100% focus on value.

Q: We have heard that in the UK, the electricity regulators have essentially mandated PAS 55 as the measure of good asset stewardship and that this approach certainly helps corporate buy-ins.

T O’H: They highly encouraged it. In most industries, regulators are going to come in and say ‘Where’s your Asset Management plan? Are you working towards ISO 55000?’ and if you don’t have a plan then the regulators are going to leverage you in a very negative way. I think that, as an organization, you certainly don’t want to do it just from a regulatory standpoint, but I think its role in meeting regulatory requirements is huge and can’t be understated.

Mary: I think it’s not just the regulators, but it’s also insurance companies. They’re insuring against risk and are pretty good at validating what the status of a risk profile is in an organization, not only from a health and safety perspective, but also in regards to the risk of business loss. There’s more and more attention being paid from that community and I think we’ll see that grow in the next four years.

Q: What role do you see ongoing sustainable equipment condition assets scoring playing in good Asset Management?

Mary: I’m thinking that’s a question that’s related to the changing role of the assets in an organization and, therefore, since the role of the asset may change, then the assessment strategy may change as well. I think the answer to that question is based in how strong your standards are across your organization. It should be very easy to see how the effort is contributing to a main revenue stream, for example, and if that posture changes during the life of the asset or during the course of business, then you should have the tools and the strategy set up to very quickly make that change across the organization.

There are CMMS tools to help with that, but I encourage the user community to look at assets across families and look at ways to group and manage the assessment and recovery strategy to those changing profiles.

T O’H: Cost and scoring will allow you to plan your renewal, maintenance and replacement strategies in order to understand the condition of your assets and where they are in terms of the remaining useful life. It is a very important starting point and it is a requirement for ISO 55001 that you do have a scoring and asset condition assessment methodology to understand where your assets are.

Q: At the ISO launch, there was a discussion on insurance premium reduction with ISO programme efforts and certification. Where do you see this?

T O’H: We published a book called Engineering Asset Management from an Insurance standpoint and the Chief Engineer writes it from AIG. The way he puts it is that the insurance company will almost view your assets as their own assets and so they want to make sure you’re providing good stewardship. So yes, there is a possibility of an insurance discount for good practices versus poor practices, but he said it should be viewed in the lens of you’ll actually get somebody to cover your risk, as opposed to not get somebody to cover your risk. He said some organizations that they go to, and they do their rating inspection, they won’t provide the risk insurance because the asset management practices are so poor. So, although I think you could aspire to earning your way to asset management through insurance discounts, I think he provides a very healthy and stark point of view that just says ‘You’ll be lucky to get somebody to cover your risk if your practices are poor’. But I guess you might expect lower premiums if you are doing good practices, that you’re aware of risk and you’re managing the risk to the delivery of the business objectives.

Q: Do you see municipalities heading toward these standards, as well as the corporate companies?

T O’H: I would say absolutely. In fact, I think it might be first, and my understanding is that, in Europe, it’s exactly those companies that have begun the process earlier than the commercial companies. As was said earlier, energy, utilities and oil and gas, rail infra-structure companies, they are the first that have adopted this standard and it makes sense for them to do so. Those companies that work on the public good, they want it held in custodianship for them, as they would manage for themselves. They want to make sure the stewardship and the value is there, and I think PAS 55, in the beginning (and ISO 55000 in the future) creates that framework to assure the people that are being served that their assets are being stewarded in a positive way.

ABOUT THE AUTHORS AND SPEAKERS

Terrence O’Hanlon, CMRP is the publisher of Reliabilityweb.com, Reliability® magazine and Uptime® magazine. He is Certified in Asset Management by the Institute of Asset Management and is an SMRP-certified Maintenance and Reliability Professional. He is the acting Executive Director of the Association for Maintenance Professionals (AMP) and the executive editor and publisher of the 5th Edition of the Asset Management Handbook. A voting member of the US TAG (PC251) for ISO 55000 – ASTM E53 Asset Management Standards Committee, he has recently been selected as the sole US Representation through ANSI for ISO Working Group 39 to create a standard for competence in assessing and certifying asset management programmes known as ISO 17021-5. He was recognized by SMRP as the 2013 Certified Maintenance Reliability Professional of the Year.

Maura Abad is the Global Asset Manager and Coordinator for Reliabilityweb.com and Uptime magazine, where she supports the growing body of knowledge in English and Spanish to deliver the triple bottom line of People, Planet and Profit. Maura leads the Association for Maintenance Professionals “Imagine Reliability” virtual Special Interest group for Latin America and is also the leader of the Institute of Asset Management NextGen for North and South America. The lead proctor for the Certified Reliability Leader examination, she is currently progressing through the Certified Reliability Leader “Train The Trainer” programme with the goal of being a Certified Trainer in 2015.

Mary Bunzel is IBM’s Worldwide Industry Leader for Manufacturing.

Eric Luyer is Global Marketing Manager for Smarter Infrastructure Management, and has a special focus on positioning Maximo Asset Management in manufacturing industry.