ABSTRACT

It is explained that although industrial lubrication can be an operation of considerable scale and complexity, as well as importance to efficiency and profitability, too many organizations, world-wide, remain unaware that its effective management requires specialized software, too often leaving it, in full or in part, to human memory, spreadsheets and/or unsuitable CMMS/EAM systems. The features and benefits (energy saving, clarity of responsibilities, history recording for failure analysis, etc.) of well designed managerial software for achieving lubrication reliability are outlined.

Reliable lubrication is an extremely important and complex operation, but one which is not being adequately addressed by corporations world-wide. They give focus to important operations such as managing accounts receivable or accounts payable, inventory control, customer relationship management, and a host of other functions. In fact, no corporation would dream of running these complex activities without the advantages of software designed for the specific purpose. Yet these same organizations remain unaware that industrial lubrication is yet another complex activity requiring specialized software.

Reliable lubrication is an extremely important and complex operation, but one which is not being adequately addressed by corporations world-wide. They give focus to important operations such as managing accounts receivable or accounts payable, inventory control, customer relationship management, and a host of other functions. In fact, no corporation would dream of running these complex activities without the advantages of software designed for the specific purpose. Yet these same organizations remain unaware that industrial lubrication is yet another complex activity requiring specialized software.

Think about it for a moment. Most industrial plants consist of a variety of plant items numbering from the hundreds to the thousands, each one typically comprising many component parts requiring lubrication — motors, drive-shafts, couplings and so on. Having many lube points per item results in thousands upon thousands of individual points to be serviced. And the whole lubrication programme is even more detailed.

DO THE MATHS

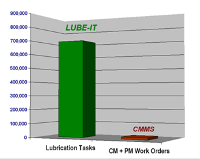

Each individual lubrication point often requires many different activities to be performed, each at its own frequency. For example, proper care of just one point will require topping-off a reservoir each week, drawing a lab-sample every quarter, and draining and refilling with fresh fluid once a year. Several thousand lube-points, each with multiple tasks at varying frequencies — it easily works out to be hundreds of thousands of activities needing to be performed annually. This means that to ensure ongoing performance and reliability many plants should be performing over 250,000 lubrication activities each year. In fact, a proactive and successful US East Coast paper plant reports performing over 700,000 such activities annually.

Now consider the problem of so many lubrication points spread across several acres, many buildings, or many storeys. This is even further complicated by the need for an array of required lubricants and the fact that distinct procedures are often required for each of the activities performed at a lubrication point. How is this daunting task being handled? Unfortunately, it’s often left, in full or part, to human memory.

COMMON WISDOM

Relying on human memory

In some cases lubrication maintenance personnel have been tending the equipment for years, resulting in detailed understanding of the needs. Hopefully, such personnel are never sick or on leave. Or worse yet, what are the consequences when just one resigns or retires? A mission-critical information asset is lost as he walks out of the door. This starts a long and costly programme of re-assembling the detailed and lost knowledge. Meanwhile, lacking experience, how does the new person on the block possibly lubricate without significant omission?

Relying on spreadsheets

Another widely used method is to follow the computer spreadsheet. Typically, this comprises a list of equipment along with numerous columns for lubrication specific data fields such as lubrication points and type, required lubricant, lubricant capacity and the frequencies at which to perform tasks. While able to convey the basics of what needs to be done, and how often, such spreadsheets fail in knowing or communicating what specifically needs to be done and when.

Most often lacking is the tracking of dates last completed — accurately entering this information for thousands of rows is an impossibly arduous task. Yet while updating spreadsheets proves difficult accidental changes and deletions come all too easy. Knowledge of last-done is the key prerequisite to determining when individual tasks are next due —without which the all-important questions remain unanswered. Which tasks are to be done this week? Which were missed last week? Also consider the hundreds of activities carried out at longer intervals, such as those performed every quarter, six-months, or year. It’s simply not possible to correctly remember when each activity was last completed. Once again the burden for proper lubrication is consigned to human memory.

Relying on standard CMMS/EAM systems

A third common approach is attempting to properly execute lubrication using the PM system of a CMMS or EAM product. Focused on CM and PM work-order management, these systems perform the role well, and most maintenance professionals are comfortable in their use.

Alas, comfort in a system’s intended function is far from the best reason to apply it to other uses. Outside the CMMS are hundreds of products supporting additional reliability disciplines such as vibration monitoring, IR thermography, and others. Why? The work-order-centric design of a CMMS is incapable of supporting the unique data and activity requirements of these disciplines. Understanding lubrication reliability to be a unique discipline is the first step toward gaining its considerable benefits.

As mentioned above, CM and PM work-orders typically number less than a few thousand annually, while annual lubrication activities can range up over 700,000. While the typical CMMS adeptly catalogues equipment at the nameplate level, these systems lack a clear approach for cataloging the multiple related lubrication points, let alone the multiple activities for each of these points. Also missing are the many data elements regularly found in the previously explained spreadsheets. The fact that these discipline-specific details are missing from the typical CMMS is the main reason such spreadsheets find common use.

This lack of requisite details leads many into a minimalist, work-order level, approach to lubrication. Simple monthly PMs are created for each equipment section or area, producing work orders with generic instructions such as ’Lubricate Stations 1 to 8’ or ‘Check levels in Bldg 12.’ Striving for more detail, one plant of an integrated forest products company was required by corporate management to use SAP to manage its lubrication programme. The plant’s reliability engineer invested months of effort on repetitive keyboard entry of lubrication details into long-text fields. Shortly thereafter, and much to his dismay, it was decided to switch more than 200 reservoirs to synthetic lubricants — leaving him to edit each individually. Furthermore, with his hands tied by data locked into non-actionable text-fields, he was forced to answer with a definitive ‘NO’ when the plant manager asked him if his time and effort had resulted in an accurate and consistent lubrication programme.

Many CMMS products allow for inclusion of a list or block of items with a PM, which can be used to list the lubrication points for an equipment area. Sounds simple doesn’t it?. Unfortunately, the actual complexities of lubrication cannot be overlooked.

Lubrication points within any equipment area are not identical. One key differentiator is the variation of frequency. Examples of such variation include some points being done weekly or biweekly, others monthly, bimonthly, quarterly or annually. A single PM can’t address this fact — resulting in multiple PMs being created, one per frequency, for each equipment area. Equally important variations include the lubricant required, number of lube fittings, and activity type (top-off, change-out, sample, etc.). Further variation comes when activities require specific step-by-step procedural instructions. With the CMMS offering no native support for lubrication how is such information conveyed using a single PM? How many PMs are needed to convey a bare minimum of these compulsory details? Remember, give a CMMS more PMs and it will return the favour with yet more work-orders and paperwork. More importantly, within these numerous work orders and pieces of paper there is no opportunity to bring optimization and efficiency to lubrication.

What’s done is done. Or is it? Mark a work order as completed and the entire block of lubrication points share the same status. A PM system unable to function below the work-order level can’t meet the need to remember that all outstanding lubrication points must be seen to over the subsequent weeks until completed. It’s not hard to see this problem compounding week after week. So having a multitude of detail-deficient lubrication PMs might look and feel good on the surface, but it veils reality with a false sense of security. Once again, the details required for success are left to the imagination and memory of lubrication personnel. With such reliance upon manual effort, paperwork and human memory, it’s no surprise that a recent search across popular CMMS/EAM websites for the term ‘lubrication’ returned zero pertinent results.

Customizing CMMS/EAM systems

The fourth and by far the most costly approach is customization of the CMMS / EAM product for lubrication. Gaining rudimentary lubrication-control capability consumes hundreds of man hours, with one organization reporting having spent nearly a million dollars to modify SAP PM for lubrication-point level of functionality. Even if successful such customizations prove difficult and expensive to update. Personnel doing the original work are often otherwise assigned or no longer part of the organization. With corporations working to eliminate maintenance of in-house legacy systems, why should lubrication be any different?

COUNTING THE COST

Regardless of perception, it’s not a case of just the tin man with an oil can. In today’s competitive environment the good old “Oil is oil” mentality does not suffice. This results in lubrication points being consistently maintained incorrectly, or worse yet, missed entirely. Yet management often declares or assumes lubrication to be in good order. You don’t get immediate feed-back when a lube point is missed. Often it takes months or even years until the feed-back manifests as costly equipment failure and unplanned down time.

This points to why over fifty percent of all equipment failures are traced back to poor lubrication practices. Numerous long-term studies in Canada, Germany, Russia, the United Kingdom, and the United States declare this fact in unison.

So this prompts the question, why are these four approaches to lubrication so often employed? Organizations tend toward them rather than to a true lubrication reliability programme for any of the following reasons:

- Lubrication Reliability not being understood as its own discipline

- Intuitive unease as to the detail and volume of activities required

- Management failure to calculate the cost of poor lubrication practices

- Management failure to calculate the payoff of lubrication reliability

- Lack of awareness of effective alternatives

What is the net result of relying primarily on human memory? It is significant cost and loss, which includes unplanned downtime, premature replacement of capital equipment, poor use of human resources and environmental risk. This is in addition to poor production quality and excessive energy consumption.

GAINING THE BENEFITS

Responsibilities become clear and known

What are the features and benefits of a well designed lubrication reliability software solution? Headaches and complexities are resolved. Maintenance planners and reliability professionals gain time to focus on other important initiatives. Most importantly, all lubrication specific details are clearly presented to lubrication personnel, ensuring lubrication is done right, which means that the right lubricant is used in the right place, at the right time, following the right procedure. Abnormal machine conditions are also noted, recorded and tracked until they improve. Other important capabilities include: consumption tracking and trending, shutdown/outage planning and display of lock-out/tag-out safety information.

A good system will include an automatic lube-point/lube-task based work release. Tasks are released individually, and only as needed, not as blocks of work. These lubrication work assignments are automatically pushed to those responsible via footstep efficient routes. This frees maintenance planners from the detail of lubrication so they can focus on PMs and corrective work. Such a lubrication reliability system will also provide automatic backlog management. Individual lube-tasks, if not complete, are automatically marked past-due and brought forward each week until they are done — with no user intervention required.

Mobile computing for accuracy

The best systems also provide for rugged handheld computers using Windows Mobile™ operating system. This brings a great deal of efficiency to the system, with information literally at the finger tips of the lubrication specialist. No paperwork and no clipboards. Fingertip data collection includes work accomplished, consumption volume, and equipment problems and issues, all with no keyboard data entry. Mobile routes will also include provisions for positive verification of tasks performed via Bar-Code or RFID, as desired.

The best systems also provide for rugged handheld computers using Windows Mobile™ operating system. This brings a great deal of efficiency to the system, with information literally at the finger tips of the lubrication specialist. No paperwork and no clipboards. Fingertip data collection includes work accomplished, consumption volume, and equipment problems and issues, all with no keyboard data entry. Mobile routes will also include provisions for positive verification of tasks performed via Bar-Code or RFID, as desired.

Safety, energy savings and oversight

It’s the detailed management of lubrication which enables a system to provide a wide array of lubrication reliability benefits. Benefits such as safety requirements accurately and clearly presented, right at the lube-point. Gains in efficiency and elimination of backtracking by simple use of drag and drop to re-sequence tasks within a route. Significant simplification of lubrication consolidation — thanks to the system’s exact knowledge of lube product usage. These lube-point details allow for the straightforward implementation of lubrication ODR (Operator Driven Reliability). In addition, there will be a procedure library which provides task specific work-steps and eliminates repetitive data-entry.

Equally important is detailed history for each lube-point as well as lubrication-specific reporting. This detailed history is required for KPI oversight as well as for process improvement and failure analysis. It also enables international standards and audit accountability. Lubrication-specific reporting brings forth information at both detailed and management overview levels. Providing instant understanding of programme status, reports will be in both tabular and graphical formats.

An added bonus may be energy management experts finding improper lubrication to be a major contributor to energy consumption. Applying the right lubricant in the right amount consistently reduces friction with the net result of using less energy. With proper lubrication practices a gain in energy efficiency of as much as 20% has been reported.

REALITY AND RESULTS

By addressing the Number One Cause of equipment failure, reactive maintenance work decreases and overall plant reliability increases. Plants gain a focused and efficient lubrication reliability programme, including footstep-reducing lubrication routes. Each route directs personnel from point to point, showing needed information, including detailed procedures. This eliminates the need for numerous PMs and the ongoing array of printed work-orders. All of which results in a significant increase in reliability and productivity.

In short, a lubrication reliability software solution will do the following:

- Reduce costly downtime and failures

- Maintain mission-critical knowledge assets

- Mitigate the impact of human factors

- Maximize employee effectiveness

- Cut soaring energy costs by up to 20%

Best of all, any one of these will quickly save more than the costs of the lubrication reliability solution.

With these benefits, and the rapid return on investment, it is difficult to understand why corporations continue to ignore this profound opportunity for increased competitiveness and profit year after year.

THE AUTHOR

has over thirty years of high-tech and industrial software experience and is the principle architect of LUBE-IT, the world’s leading lubrication reliability software solution, and is guiding his company toward its 25th anniversary. He has concerns regarding the increasing complexity and bloat of industrial software and this, coupled with his regard for end-users, drives him to innovate comprehensive, yet highly intuitive solutions.