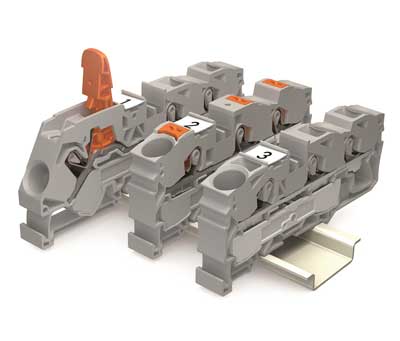

Interconnection specialist WAGO introduces push-button and lever-actuated variants to its TOPJOB S® terminal block family, giving integrators additional flexibility on DIN rail installations.

The lever-actuated variant, a world first from WAGO, is equipped with a lever on the field side and a push-button or operating tool-actuated connection on the factory side.

The clamping point on the field side is opened and closed by hand using the lever, allowing installers to tell at a glance which wires in an assembly are terminated. The lever can also be left open, freeing both hands to connect difficult-to-bend conductors with large cross sections.

Versions are available for nominal cross-sections of 2.5 mm², 6 mm² and 16 mm², and in 2- or 3-conductor configurations.

The clamping point of the push-button mechanism is opened by screwdriver. Feed-through terminal blocks with push-buttons are available for wire with a cross-section between 0.14 to 25 mm². The push-button terminal block is available in 2-, 3- or 4-conductor variants.

All TOPJOB S rail mounted terminal blocks feature Push-In CAGE CLAMP® spring pressure connection, which is 50% quicker to wire compared with screws and immune to loosening over time. The terminal blocks are also resistant to vibration and overcurrent and free from maintenance.

www.wago.com/gb | 01788 568 008 | paul.witherington@wago.com