A cooling system breakdown in a cold storage warehouse requires fast action to avoid product spoilage. Matt Watson of mobile power and temperature control equipment supplier Aggreko explains how emergency cold storage units can resolve a potentially catastrophic situation.

Cold storage warehouses are subject to extremely stringent quality controls, with the cooling system keeping the air temperature at -22°C or below to maintain product integrity. Even a slight variation in temperature from an influx of ambient air can prove extremely problematic, with affected stock often requiring disposal at large financial cost.

If a breakdown occurs, it is standard for the store manager to lock down the affected store to maintain the temperature for as long as possible – most likely a few days. But this can affect the supply chain the store serves, so decisive action within this tight timescale is crucial to preserving product integrity.

Fast response

Traditionally, the response to a breakdown would be to install a refrigeration solution with several air handling units (AHUs) inside the affected site, and chillers and hoses outside. This can take a few days to set up, with the temperature, and the risk of spoiled stock, constantly rising. Though the installation may restore the temperature and store operations, thousands of pounds worth of goods might still need to be thrown away.

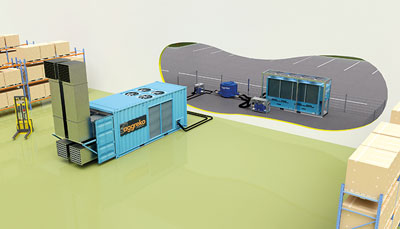

Instead, the problem can be remedied through the use of temporary air-cooled low temperature direct expansion air conditioning units, which can also be used in blast freezing and holding chill applications. Housed entirely in a single, easily-transportable container alongside an AHU as part of an emergency cold storage solution, they can be quickly installed, rapidly bringing down the store’s temperature to normal levels with minimal disruption. The fast set-up speed means goods needn’t be thrown away, or decanted into another cold store, which can present logistical and financial difficulties.

Single container

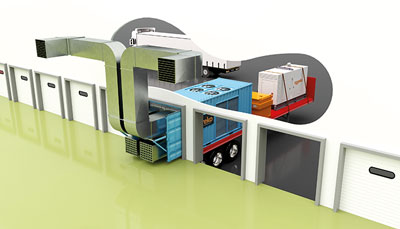

The unique all-in-one design can be seen in emergency cold storage units from Aggreko, with chillers and AHUs housed in a single container designed to fit a loading bay when trailer-mounted, and a maximum current rating of 285A. The innovative design means such a unit can be set up and installed as a practical emergency response solution within four to six hours. It can also be operated entirely externally in tight plant environments, and can be converted into a water-cooled system where there is insufficient space for an external installation.

As a result, installations are more cost-effective, shorter and logistically simpler – vital concerns during system breakdowns, where a quick, effective response is of paramount importance. The quicker installation speed also gives owners and operators more time to consider their next step following the breakdown.

Adaptable solutions

As well as guarding against unscheduled downtime, such temporary cold storage solutions can help maintain storage capacity during planned shutdowns with minimal disruption – for example, while a fixed cooling solution is being maintained or upgraded. They also offer cold storage warehouse operators a way to increase capacity for products such as pharmaceuticals and food during periods of high demand or uncertainty.

In these scenarios, a temporary solution can allow operators to transform ambient-temperature storage space into a cold store, while making sure the warehouse meets the strict temperature quality control requirements covering chilled and refrigerated products.

Opting for a temporary solution means operators do not need to install further permanent chillers or chilled air distribution systems when faced with spikes in demand, avoiding the prolonged, added strain on existing plant infrastructure that makes breakdowns more likely. Furthermore, for sites not connected to the National Grid, or operating at full power, temporary generators can be used to power the entire unit. This means cold storage warehouse capacity can be increased quickly, safely and easily when required, giving the operator and supply chain peace of mind over product integrity.

In conclusion, emergency cold storage units hired on a temporary basis offer a solution to the two main risks confronting companies reliant on cold storage warehouses: sudden cooling system failure and insufficient capacity during periods of peak production and high demand.

www.aggreko.com/en-gb/products/cooling-rentals/chiller-rentals