World-first technology being developed in the UK for the remote repair of pipelines is nearing the end of its proof of concept stage, with trials set for early 2021. Peter Routledge, Forth Engineering programme manager, explains.

Robotic pipeline technology with potential to revolutionise performance in industries around the world has successfully completed its latest milestone on course for trials in 2021.

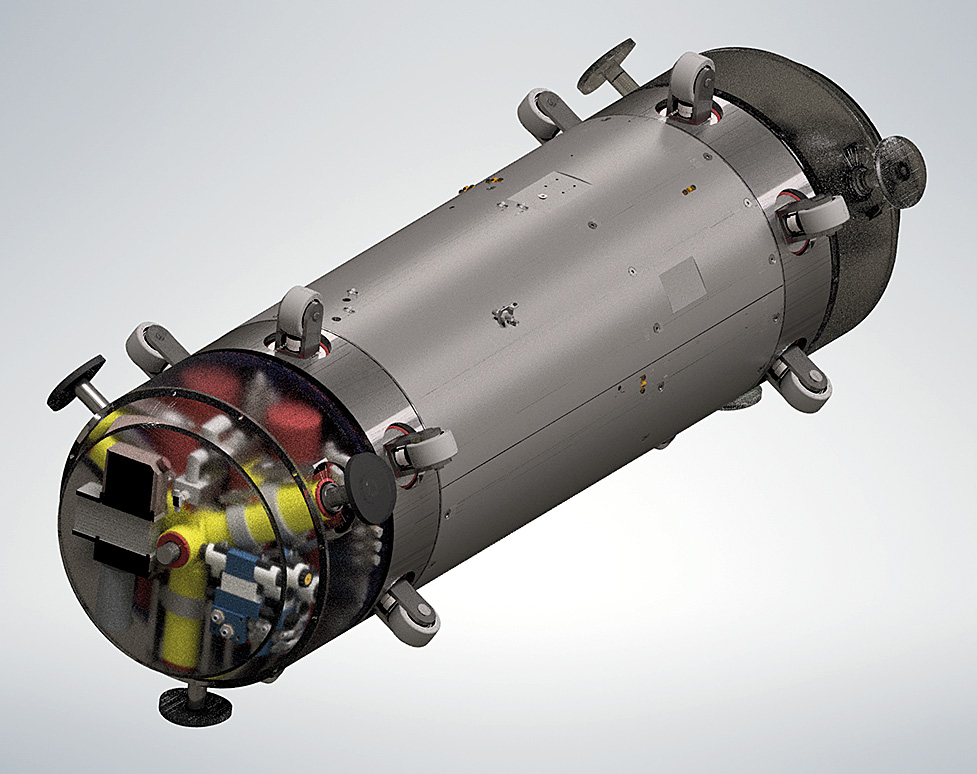

The development of the FSWBot, or friction stir welding robotic crawler for internal repair and refurbishment of pipelines, is designed to transform the way industries deal with pipeline defects.

Led by Forth Engineering in Cumbria, the FSWBot project has been attracting attention from around the world ever since being first showcased in Aberdeen last November.

Forth Engineering is working with a consortium comprising welding research institute TWI, Joining 4.0 Innovation Centre (J4IC, a partnership between TWI and Lancaster University), and London South Bank University school of engineering on the project, which is expected to have a major impact on safety in the industry.

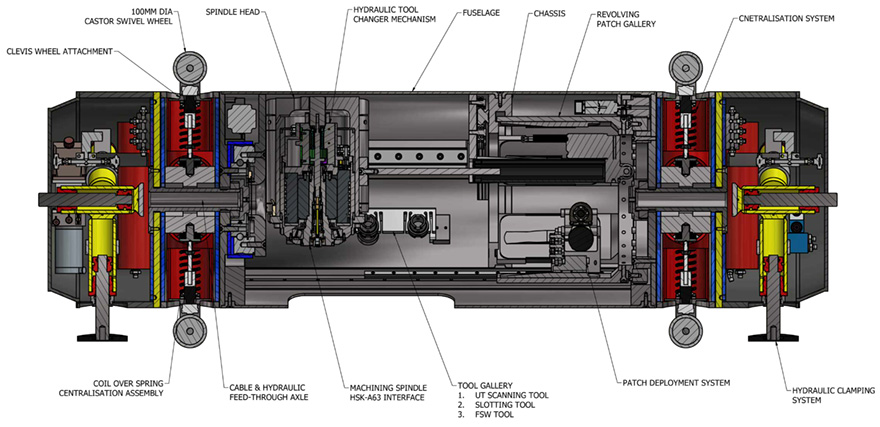

It is sponsored by Innovate UK, which provided funding in 2018 for the consortium to develop a proof of concept system. The project seeks to integrate several state-of-the-art technologies including friction stir welding, milling, patch deployment and ultrasonic non destructive testing on a robotic system which can be used to conduct repairs on pipelines, without the need for the pipeline to be closed down.

If successful, it is envisaged that the system could be developed further to carry out a range of repair and fabrication tasks.

The FSWBot programme has remained on track throughout lockdown thanks to the work of all partners. In the latest milestone, Forth successfully demonstrated the hydraulic system (for clamping, walking and crawling) using automated controls.

It has also completed 90% of its work on the FSWBot fuselage, which is on course to be finished in October.

Collaboration between Forth and LSBU on the controls elements is also continuing and due to be completed January 2021. All this puts FSWBot on course for planned trials in late January or early February next year.

Friction stir welding is a solid state welding process which generates enough frictional heat to soften or plasticise metal without melting it, allowing components to be forged together at the joint line. The proof of concept system will demonstrate that, using FSW, a patch weld can be made in steel pipe under oil, and that a representative FSW system can be made small enough to operate in a 36-inch diameter export pipe.

The FSWBot is envisaged to be a five or six segment PIG-type vehicle which will be inserted at the production end of the pipeline and will travel with the oil flow to a pre-designated spot to perform a repair.

One segment will carry the FSW machine and a steel patch dispenser, with the other segments carrying the navigation, control system.

On entering the pipe segment containing a previously identified defect, such as corrosion, the FSWBot will stop, then slowly advance until the FSW system is positioned over the defect. It will lock itself in place and confirm that it is correctly located to perform the repair.

An onboard turbine in a duct in the FSWBot will harvest energy from the oil flow in the pipe to augment power cells carried on the system.

Once energised, the FSW unit will use a milling tool to mill away the corroded area and prepare a pocket in the pipe wall into which a steel patch will be dispensed.

The FSW unit will then weld the patch in place, then use the milling system again to make sure that the patch is flush with the pipe wall so that it will not initiate turbulent flow or impede the passage of subsequent cleaning or inspection PIGs.

FSWBot will then use NDT technology to inspect the weld for quality assurance purposes before unclamping itself and moving downstream to repeat the process on any further defects.

Next year’s trials plan to demonstrate the operation of the clamping and crawling system in a 12m long purpose-built test rig, as well as demonstrating the FSWBot milling operation, the automated patch deployment system, a full demonstration of FSW friction stir welding into the patch area and finally a ultrasound scan of the friction stir weld.

The FSWBot is attracting interest from different industries around the world and the consortium wants to hear from companies and sectors which might have an interest in the system.