Sustainability is as important in the scaffolding and access sector as in any other, says Sean Pike, UK managing director of Layher.

A focus on environmental performance – in all its aspects – is, today, high on the agenda of all responsible companies, and a committed and active approach to the issue has become central to success.

Greater emphasis on achieving greener performance means that every aspect of production and engineering activity now seeks to accommodate this objective – from manufacturing and operational processes to optimising broad associations with local, national and international communities. It is a viewpoint that encompasses both economic and ecological sustainability, with a focus not only on using production processes that preserve resources but also on a commitment in areas such as construction and transport.

To support this drive, system scaffolding, access and weather protection specialist Layher has created a dedicated energy management team at its manufacturing plant near Stuttgart, which uses the international standard ISO 50001 as the basis for all activities and processes that call for the consumption of energy.

Alongside this, the company has identified the sustainability of its production processes, the means of measuring performance and the design of the products themselves as three key factors that come under the green spotlight, committing itself to a 10% reduction in energy consumption in its production processes over the next ten years.

Its methods include a move towards optimising movement between manufacturing locations to help reduce carbon dioxide emissions, the acquisition of raw materials that are ecologically sustainable, and the use of machinery that operates in the highest energy efficiency class. Similarly, the use of new production technologies and processes that seek to preserve of resources can be seen through the company’s focus on using innovative technology such as combined heat and power and heat recovery facilities.

The organisation believes that it is vital that this approach is continually subjected to a reliable means of measurement, to demonstrate its performance and also identify areas where further improvements can be made. The replacement of diesel forklift trucks with electric alternatives, installing photovoltaic systems and incorporating green spaces in new building plans are all examples, as is the reduction of waste materials, often to create an alternative energy source.

Layher also believes that product design should itself reflect the green imperative. For example, being able to combine new equipment with existing materials and stocks can help to optimise the long-term use and versatility of scaffolding, weather protection and access solutions. It is a view that is echoed in the organisation’s commitment to make sure equipment approvals remain applicable across successive design generations.

Layher’s belief in the use of lightweight materials plays an important role in this regard, not only helping with operations on site but also contributing to minimising transportation needs and reducing emissions.

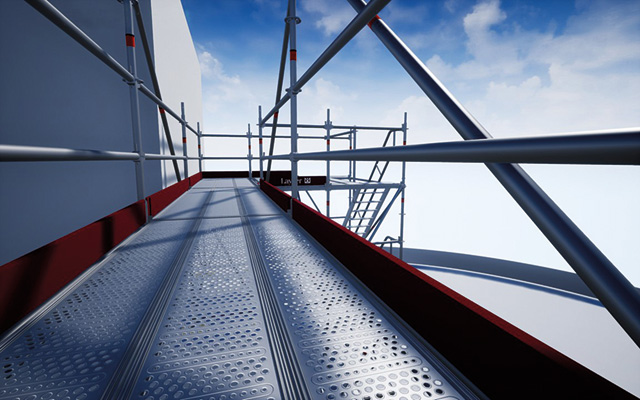

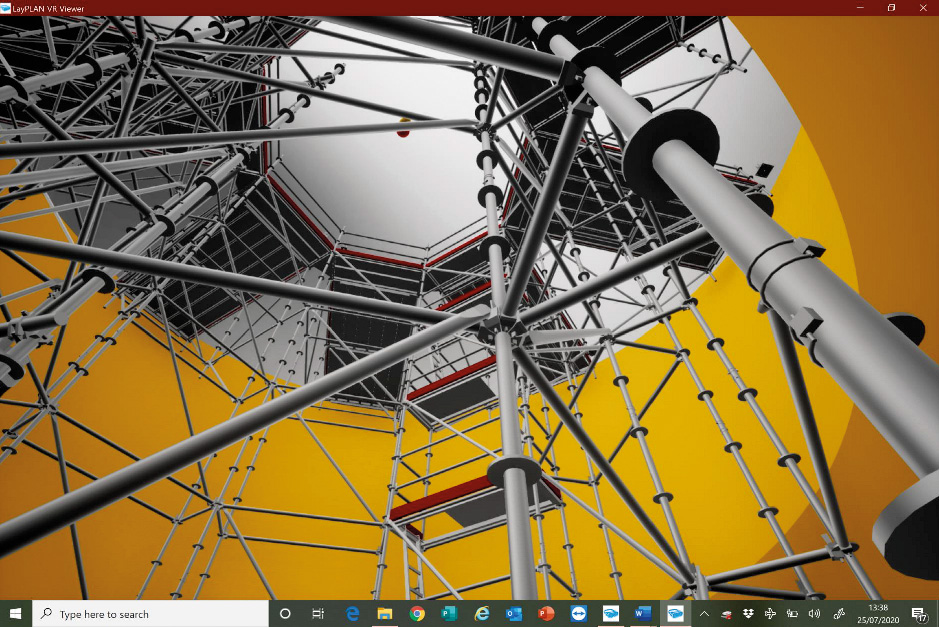

One of the most dramatic recent developments by Layher has been its Scaffold Information Modelling (SIM) software. Here too, environmental gains can be noted. SIM is designed to help with planning operations, which in turn can maximise installation efficiency, reduce risk and save costs.

It enables users to create 3D visualisations either on screen or via a VR headset, which takes them into a digital world where scaffolds can be rotated, flown-through and readily adapted before outputs such as material needs, weights and logistical details are produced. Because the design tool provides a highly versatile planning method that allows improved presentations, and communication with mobile devices via cloud-based mixed reality, it can reduce the need for multi-party meetings and operations. Again, this can help cut down on travel requirements and consequent emissions.

Via its head office in Letchworth and satellite depots in Yorkshire, the West Midlands, Scotland and Ireland, Layher believes this focus on sustainability should go hand in hand with the maintenance of stock levels and support during the current challenging times.

With a firm support base in place, optimising our – and our customers’ – environmental performance can be realised by the optimum integration of a broad range of actions and structures that always accommodate the green objective. It is a philosophy that will be recognised and appreciated by everybody in the manufacturing, maintenance, and engineering sector.

Further info: Sean Pike | 01462 475100

info@layher.co.uk | www.layher.co.uk