LED lighting technology allows efficient visual communication in the workplace of a wide range of information on machine operations, with benefits for safety and efficiency, says Calum O’Connell, business development manager at Turck Banner.

With today’s technology and thirst for information, it is sometimes easy to miss the simplest of solutions. That does not mean that some simple things cannot be improved.

Most companies seeking to improve production acknowledge that empowering the workforce can produce huge gains. The growing trend for smart factories is providing operators with ever-growing quantities of information. How that information is distributed and presented is critical in improving workplace efficiency and the working environment.

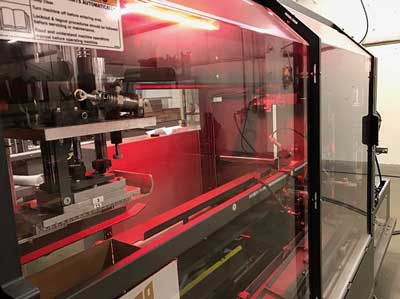

Information should be presented as it is needed. For example, if an emergency stop is pressed on a machine, what does the operator or any other person in the vicinity need to know? Typically the machine may have a tower light showing either green or red to indicate the machine is running or stopped, and there may be an interface displaying the E-stop location, or a simple location number. Guiding the operator to the machine in question by using illuminated E-stops and having the machine lighting turn from white to red in the affected area would be a much better use of the information.

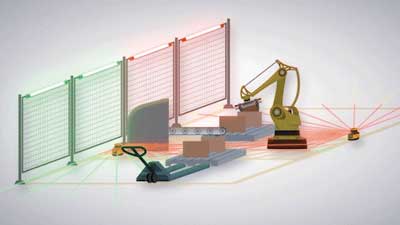

Another example of improving safety and efficiency is in a robot-operated continuous palletising process. As floor scanners are often used to protect the area around the robot, the operator needs to know when it is safe to enter the area without tripping the safety system.

By using coloured LED lighting, the area that is safe to enter can be illuminated green, while the area in which the robot is currently active is illuminated red. When the robot completes its task in one area and moves to the next, the illumination colours change to indicate the new conditions.

Indication is not limited to red and green. The full spectrum of colours can be used. This can be combined with animation and sound to convey a range of different operational conditions, effectively giving your machine its own voice. The design team needs to prioritise making the system immediately understandable and avoid over-complication. With careful thought, and guidance from the experts when necessary, complex information can be imparted in simple, efficient ways.

A small number of unique colours can indicate a number of machine conditions, including the current process in a multiprocess operation, the running speed or efficiency. Machine startup could be indicated by animating the tower light to produce a circling effect in the lights.

In fill level applications, the fill level is usually indicated by a red, amber, green tower light, which tells the operator if the level is full, approaching empty, or empty. Replacing this old technology with a full colour, multi segment LED tower light can show the percentage fill level, while the segments can change colour as the level approaches the critical stages, thus allowing operators to use their own judgement on the timing or sequence of operations required.

Turck Banner has a vast array of LED lighting and indication products specifically designed for industrial use. In the 1960s Banner Engineering was a pioneer in LED technology used for sensing products. It worked closely with the LED manufacturers to develop LEDs that are reliable, stable in their light output and have a working life in excess of 50,000 hours. It has used its 50 years of expertise in optical sensing products to develop LED lighting and indication with the same quality, reliability and industrial housings.

As a result, the use of visual indicators to impart information from a distance can make huge improvements in workplace efficiency and safety, and to the overall environment.

Further information: Calum O’Connell, business development manager (Banner Specialist), t: 01268 578888

calum.oconnell@turckbanner.com

www.turckbanner.co.uk