Establishing a carbon emissions baseline by the end of 2022 represents a crucial first step for manufacturing firms committed to tackling their carbon footprint according to a new net zero roadmap for the sector which was published this week.

The report from Make UK and Inspired Energy says the manufacturing industry “overwhelmingly supports” an ambition to achieve a 67% reduction in Scope 1 and 2 emissions by 2035 on its pathway to the net zero goal.

Firms must measure their baseline for these operational carbon emissions within the next 12 months, the roadmap proposes, and should aim to have net zero strategies in place by early 2023 ready to begin implementation.

Although the drive to net zero presents major opportunities for manufacturing, the report adds that industry’s ability to take “meaningful” action will be conditional on Government laying out the necessary policies and providing the right level of support.

“The release of the first roadmap to net zero for the overall manufacturing sector marks the start of an exciting journey, with its challenges but also many rewards ahead,” said Make UK chief executive Stephen Phipson. “I am very proud that our members have not hesitated to take up the challenge and are bold in their vision.”

According to the Climate Change Committee, the manufacturing and construction industry is the third most polluting sector in the UK and was responsible for 13% and 18% of greenhouse gas emissions in 2019 and 2020 respectively. Approximately 90% of emissions from the sector come from manufacturing activity, with over 85% of these produced by fuel combustion and the remainder originating from process emissions.

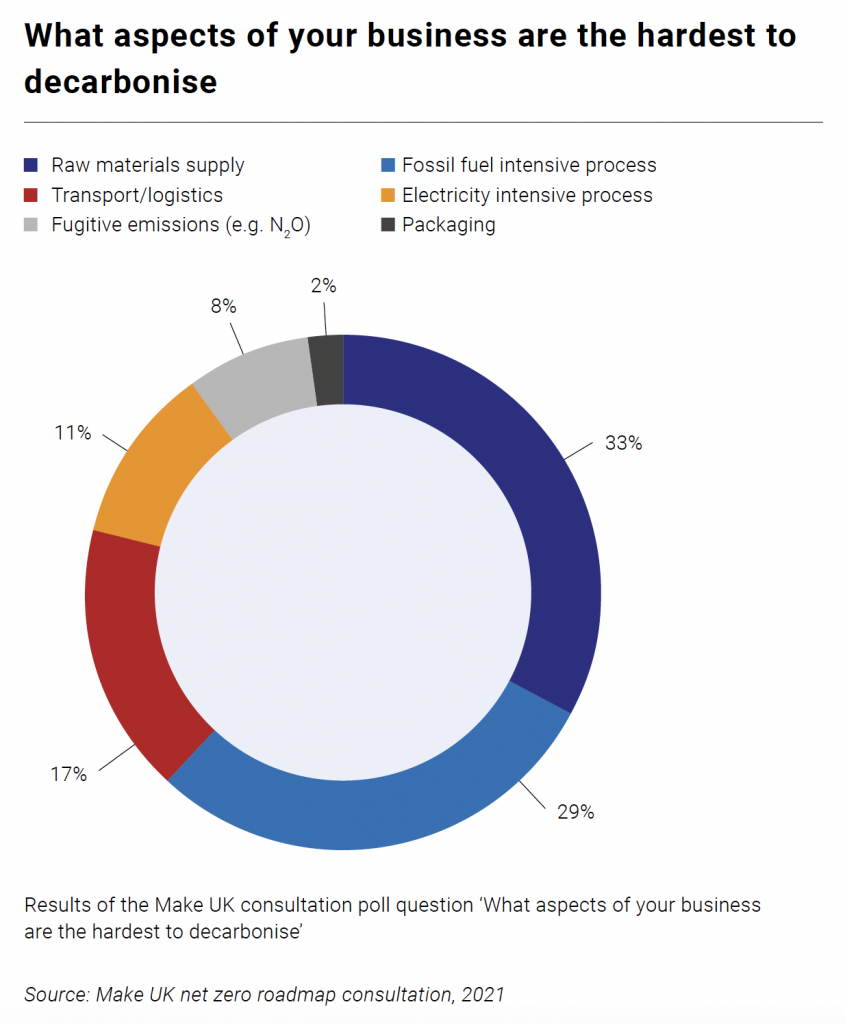

Decarbonising fossil fuel intensive processes, the supply of raw materials and transport and logistics were identified by Make UK members as the hardest aspects of their operations to decarbonise.

The report highlights that changing existing processes and workflows can be costly and innovation will be required to develop new low carbon alternatives in these areas. However it emphasises that although upfront costs can be high, once changed processes are often more operationally cost efficient.

Reducing emissions and staying cost competitive is a further key concern of the manufacturing industry, which should be supported with the correct policies to reduce risks associated with the transition to net zero, the report says.

Main asks of government include additional funding support around capital spend incentives, subsidies for the cost of electricity and grant funding.

SMEs in particular have trouble identifying funding opportunities; a clearer and streamlined funding landscape is therefore needed to ensure finance is accessible to all manufacturers, it adds.

The report also calls for an expansion of the scope of funds available to include the upgrade of standard equipment such as pumps and compressors to modern energy efficient versions, and the installation of energy information management systems or building management systems to help control energy use.

A further call for action is that the government, training providers and manufacturers should make greater collaborative efforts to address the green and digital skills gap.

Meanwhile, in addition to measuring and devising strategies to reduce Scope 1 and 2 emissions, manufacturing firms should also begin thinking about their indirect Scope 3 emissions, the roadmap proposes.

It suggests that all manufacturers should start screening and identifying their Scope 3 emissions and engaging with their value chain to gauge the willingness and potential of their suppliers and customers to reduce their own emissions.

To view the roadmap, click here.