mechanical vibration data across a fleet of machines

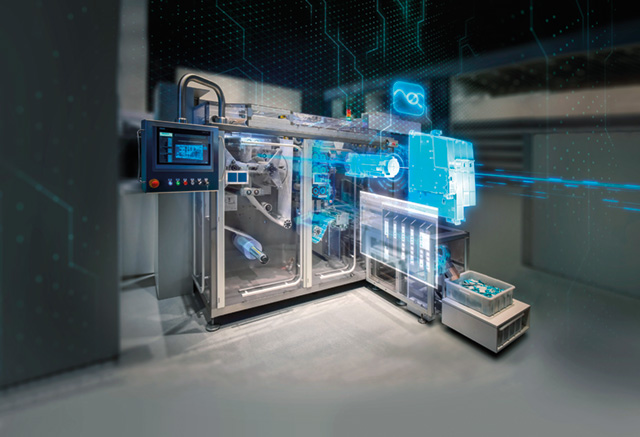

Critical condition monitoring data can be gleaned from IoT connected drives, without the need to introduce external sensors, writes Rohan Beck, digital drive train technical specialist at Siemens Digital Industries.

When considering condition monitoring for a drive train – particularly when retrofitting a monitoring system onto an existing machine – many engineers’ first thought is to consider the sorts of sensors to buy and where to fit them.

While adding new sensors is a valid route for condition monitoring, they may well be unnecessary. It is important to understand what existing data is available and how you are using it before sourcing new data from sensors.

There is a lot of often untapped, or at least under-utilised data already available from machines; in particular those with a variable speed drive will have numerous highly informative parameters available from within the drive itself.

Modern variable speed drives are capable of being a connected part of an automation network. As such they have processors, a communication interface, and sometimes built-in memory or a way to access external storage. Some drives can negate the need for a Programmable Logic Controller (PLC) too, for certain applications.

There are even drives available that function as their own web server – or with optional modules available which do the same – allowing for commissioning, parameterisation, and maintenance of the drive to be performed on a tablet or smartphone, connected wirelessly to the drive. Even simple drives such as Siemens’ SINAMICS V20 come enabled with the capacity for wireless connectivity.

Industry 4.0 is the era for intelligent systems and many drives on the market are designed with this in mind. Each of these technologies can significantly help with condition monitoring and predictive maintenance.

Drives are not only able to communicate, but they have a lot to share – that is, drives contain incredible amounts of data, whether it is directly measured signals from their numerous built-in sensors, or processed signals derived from some combination of those measured signals, or internal monitoring data such as an error signal.

With data showing the value of parameters such as speed, torque, power, DC link voltage, output voltage, and more already available, basic condition monitoring can be achieved without the addition of sensors.

So, rather than thinking about what sensors you might need to buy to glean this data, it is better to consider how to access the information already being logged. Monitoring and analysing short- and longterm trends in the data and can provide alerts for when measurements go outside of their permissible operating values.

Depending on the application, this monitoring system might be kept within a local network on site, or it could be connected to a cloud network which allows access to the system from anywhere in the world.

Being able to read parameter values from a drive while on site is useful, but it doesn’t quite qualify as a condition monitoring solution. Cloud-based services that offer worldwide access provide the insight for remote and unmanned locations. Siemens’ Internet of Things (IoT) platform, MindSphere, is an ‘as-a-service’ solution designed to provide engineers with this single view.

Using IoT to get this view of condition monitoring is also aided now by how ubiquitous internet access is. Even when traditional wireless internet access is not available, the improvements in reach and reliability of public mobile communication networks over the last few decades, and the future onset of 5G technologies, means there are viable solutions to solving connectivity issues where no other transmission medium is available too.

With a wealth of connection options available from a range of providers, it has never been a better time to consider connecting your drives to the Internet of Things, regardless of how remote they are.

www.siemens.co.uk | rohan.beck@siemens.com | t: +44 (0) 7921 716790