Many food and beverage manufacturers rely on reverse osmosis (RO) systems for their process water. Here, Brian Jones, Business Development Manager (North and West) at Veolia Water Technologies UK highlights the importance of high-quality feedwater – and in some cases pre-treatment – for the effective use of RO.

A simple, safe, compact and cost-effective method of water purification, RO systems can remove 99% of contaminants from feed water, such as dissolved solids, organics, bacteria and pyrogens. RO systems generally use a pump to create pressure that forces feedwater through a semipermeable membrane against its natural flow. The purified water molecules then pass into a water tank while the contaminants are discharged through a reject stream. Its versatility makes RO technology ideal for a range of applications, including process water production, decontamination and wastewater recovery.

However, efficient operation of these kinds of process water systems is dependent on the quality of the feedwater. Crucially, RO systems are often combined with a preliminary water softener step to reduce feedwater hardness. These systems use ion exchange resins that attract calcium and magnesium ions and replace them with sodium ions, preventing scale build up in the rest of the water treatment plant. In some cases, further feedwater pre-treatment may be required, along with consistent servicing and preventative maintenance to ensure that the RO system performs most effectively.

For example, VWT UK was recently employed by a large-scale gin distillery in the North of England, to help combat a feedwater issue that was causing problems with the efficiency of its operational processes.

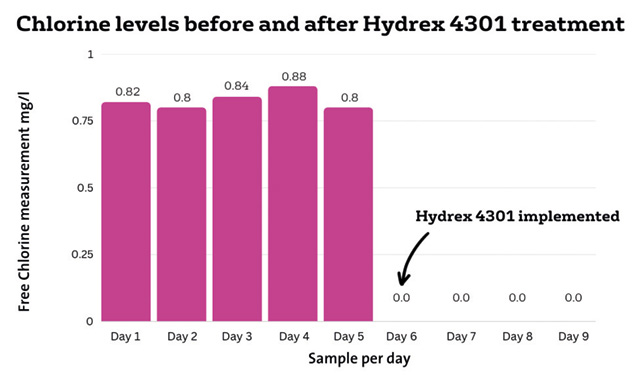

One of the oldest distilleries in the world, producing a significant percentage of the UK’s gin, the company used a set of water conditioning and RO units to process approximately 30m3/hr of raw water for use in its products. However, after moving location, the distillery suffered from an uncontrolled deterioration of the ion exchange resin beds inside these conditioning units. This deterioration was found to be due to excessive levels of residual free chlorine – approximately 0.89mg/l – in the feedwater at the new site.

In turn, these high levels of excess chlorine were impacting on the efficiency of the conditioning units and also the subsequent RO units which are vulnerable to chlorine. Chlorine is used in feedwater to prevent bug growth so it’s not uncommon to find chlorine in water in small levels; however above 0.5 it becomes destructive to RO membranes, making them semipermeable and allowing contaminants to pass through. While this issue did not affect product quality from the site, it resulted in increased CAPEX to maintain the required levels of gin production.

VWT UK was successful in a competitive bid to help reduce the presence of residual free chlorine in the feedwater to approximately 0.2mg/l, a level that would not damage the distillery’s water softeners or RO systems. One of the stipulations was that any solution was installed efficiently, to resolve the issues as quickly as possible and reduce the likelihood of any further damage.

To effectively treat the residual free chlorine for removal from the facility’s feedwater, VWT UK suggested the use of its Hydrex™ 4301 – a water treatment chemical that is specifically formulated for RO systems with polyamide membranes that can be affected by chlorine.

As it was vital that the issue could be resolved with minimal operator input, VWT UK installed a single dosing pump with flexible dosing pipework and an intermediate bulk container (IBC) bundstand. The dosing pump was then connected via a 110v lead and socket to transmit a signal to stop and start dosing depending upon whether the water feed pump was active. This would ensure that the Hydrex™ 4301 chemical was only dosed when required.

Thanks to the water treatment solution, the distillery has now been able to reduce the level of residual free chlorine in its feedwater to <0.2 mg/l and prolong the life of the components in the water softeners and RO units. Furthermore, this was achieved with extremely low usage of Hydrex™ 4301 – even lower than originally estimated – which pleased the client. With this simple and effective solution, VWT UK eliminated the need to bring in demineralised water with the use of road tankers, a process that had been required when the resin beds had failed previously.

The dosing system has now been in operation for over 12 months. Furthermore, the company has been able to accurately baseline its facility output and plan its day-to-day operations more effectively, resulting in reduced unplanned spend and CAPEX, while maintaining the same levels of gin production.

www.veoliawatertechnologies.co.uk | sales.watertech@veolia.com | t: 020 3666 0197