ABB has launched a new LV Titanium Variable Speed Motor platform that it says will is transform industrial operations worldwide by offering a forward-thinking solution that meets current needs and also anticipates future industry demands.

The platform is said to have groundbreaking efficiency, versatility, robustness, and compact design, delivering he benefits of a high-efficiency motor and variable speed drive (VSD) technology in a single, compact, customisable, plug-and-play solution that enables industrial customers to minimise energy consumption, save money and reduce carbon emissions.

ABB says the LV Titanium offers a simple and cost-effective way to provide IE5 Ultra-Premium efficiency for pumps, compressors and many other applications. As a drop-in replacement for existing direct-online (DOL) induction motors, the Variable Speed Motor provides an easy upgrade path to a VSD-driven motor with a fast ROI.

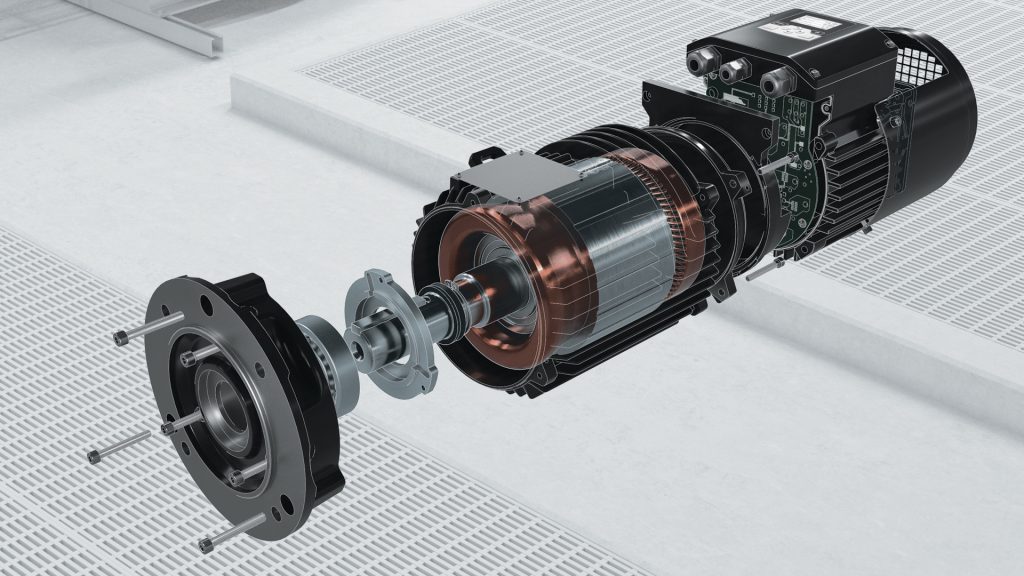

It is said to be more than a drive simply bolted on to a motor, but is engineered as a fully integrated concept, with an advanced drive module purpose-designed from the outset for optimal performance with a high efficiency permanent magnet (PM) motor. The streamlined design, with the axial drive mounted on the end of the motor, saves space and makes the LV Titanium ideal for applications like vertical pumps. It is also claimed to be remarkably quiet in operation.

An advantage of the LV Titanium is that it can operate over a wide range of speed and torque requirements, with the capability to deliver high torque at low speeds.

Stefan Floeck, Division President, IEC Low Voltage Motors at ABB, said: “We developed the LV Titanium in collaboration with customers who asked us to help them achieve energy savings and reduced carbon emissions without installation complexity.

“This Variable Speed Motor delivers just that – advanced performance in a compact, user-friendly and speed-controlled motor package that draws on our decades of application expertise.”

Plug-and-play functionality means the LV Titanium needs no commissioning, as the fully integrated motor and drive are commissioned and optimised to work together before leaving the factory. This is said to make installation fast and easy, with no need for cabinets or electrical rooms, and specially trained personnel are not required.

The LV Titanium has an intuitive control panel with customer friendly analog and digital inputs and outputs (I/O) together with a simple built-in PLC, while its connectivity features include the Modbus RTU communications protocol for easy integration with PLCs and other control devices.

Thanks to its compact design and high power density, the Variable Speed Motor is at least two frame sizes smaller than comparable induction motors, making it suitable for installations where space is at a premium, such as in replacing older, inefficient motors.

The possibilities for energy cost savings by switching to the LV Titanium are illustrated by comparing it with a conventional, standalone, fixed speed motor in a 7.5 kW centrifugal pumping application – one of the main sweet spots for the IE5 Variable Speed Motor.

The annual savings on electricity bills through using the new motor are estimated at over Euro 4,000 based on a typical energy cost for Europe of Euro 0.21/kWh. There is also a claimed yearly reduction of 6,000 kg in CO2 emissions based on the average European carbon intensity factor of 0.3 kg CO2/kWh.

The LV Titanium Variable Speed Motor is currently available in smaller sizes from 1.5 kW while the platform will expand to cover applications up to 30 kW for a wide range of industrial sectors, from water treatment and chemical processing to food and beverage. In addition to being available off the shelf, the motor can be customised to suit specific customer requirements.