Three elementary principles are vital for success when using a thermography camera. Andrew Baker, FLIR Systems North Europe sales director, explains.

When using an infra-red thermography camera for electrical inspection and data capture, accuracy is key. Whether the camera-operator is an experienced thermographer or new to the technology, an important acronym to remember is FORD – FOcus, Range and Distance.

Modern thermal imaging cameras are really clever but that doesn’t mean they can compensate for every miscalculation. Focus, range and distance are critical because none can be adjusted or corrected once a thermal image has been saved. To make sure images are meaningful and suitable for further analysis, the camera must be in focus, and images must be taken in the correct temperature range and at an appropriate distance from the target.

First, focus. As with any camera, a thermography camera must be optically focused before an image is captured. A blurred image isn’t just unprofessional; it also produces inaccurate temperature measurements. It’s simple: good focus equals better measurement.

‘Range’ refers to temperature range. The temperature of the object to be measured must be within the range setting chosen. Many infrared cameras are able to detect and measure target temperatures from -20°C to 1500°C, but they cannot do so within the temperature limits of a single image.

Most camera models break up the total temperature measurement range into a number of defined temperature intervals that the detector is able to see and image without going into saturation. The camera’s inbuilt temperature measurement will provide a spot temperature reading when you position a centre point or cross hair over the point you are interested in. From this reading you can then decide if you are in the correct range.

When an image is saved, all the data within a particular range is captured. Any temperature points which fall outside the range, however, are not. So being in the right temperature range before the image is saved is critical. This is for reasons of resolution, the ability to resolve areas of thermal detail on an object, but also to capture enough information to measure temperatures accurately.

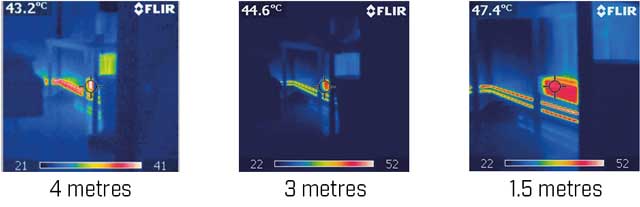

Finally, distance. An infrared image is made up of pixels, individual detectors that sense infrared radiation. All infrared cameras have limits to what they can resolve from a target of a given size at a given distance.

Resolution is a function of the number of detectors in the camera and the size, or field of view (FOV), of the lens. It’s essential the camera operator gets close enough to put as many detectors on target as possible to obtain the best resolution of the object. A good rule of thumb is to completely fill the spot circle on the measurement tool to make sure the camera is at the right distance to get the most accurate reading.

If you are struggling to fill the spot circle even though you are as close to the target as is possible in safety, switching to a telephoto lens is another option for better accuracy.

Continuous development of infrared cameras for electrical inspection has made the technology eminently affordable, easy to use and flexible to apply. Nevertheless, understanding the science behind thermal imaging is essential to its successful application, so basic training should always be considered with every camera purchase.

Email: sales@flir.uk.com | Web: www.flir.co.uk

Tel: +44 (0) 1732 220011