ABSTRACT

At a sea defence study site on the Fylde coast, in the North West of England, dairy hypochlorite is used to eradicate bio-fouling from municipal steps and walkways. This article investigates the use of sodium hypochlorite (NaClO) and describes the effects of this destructive chemical upon the innovative use of polypropylene fibres within a marine concrete matrix. Polypropylene fibres were treated with NaClO (2.5%) and an artificial seawater, NaCl (3.5%), replicating a six-month maintenance regime at the site. Modifications in visual, chemical and structural properties of the polymer were evaluated by Attenuated Total Reflectance Fourier Transform Infra-Red (ATR-FTIR) spectroscopy and scanning electron microscopy (SEM) with energy dispersive X-ray analysis (EDX) – revealing that the visual, chemical and structural properties of the fibre changed when exposed to a minimal NaClO solution. This multidisciplinary study is the first to report the composition, attachment and growth of NaClO crystals upon synthetic fibres within marine concrete, laying the foundation for more research into this new phenomenon.

INTRODUCTION

There is now considerable use of discrete fibres for the reinforcement of concrete. The author has examined the use of NaClO at a study site in the United Kingdom (see Figure 1) where this chemical, combined with power washing, is used as part of an anti-fouling strategy (see Figure 2).

Horizontal surfaces, such as road slabs and bridge decks exposed to freezing and thawing are frequently treated by de-icing agents for the purpose of eradicating snow and ice and it is well accepted these agents have an unfavourable effect on concrete. NaClO is frequently used to avert ice formation on highways, airports and transport infrastructures across the world.

NaClO is widely used for chlorination in fibre-reinforced concrete swimming pools. Well compacted and cured reinforced concretes appear to possess excellent durability as long as the fibres remain protected by the cement paste [1]. The concrete mix should be designed and cast so that there is adequate cement paste to ensure full coating of the fibre for complete bond [2]. At the site in the North West of England the local authority has been using dairy hypochlorite (DH) to remove bio-fouling, mainly algae, from its public concrete steps, sidewalks and promenade. The author has monitored the use of sodium hypochlorite (NaClO) for ten years on the Fylde coast and details here the effects of this aggressive chemical upon the innovative use of polypropylene (PP) fibres within a marine concrete matrix.

NaClO has been widely used in the cleaning of filtration membranes, can oxidise the membrane surface and cause partial scission of the polymer, resulting in changes in functional groups, mechanical properties and physical structure [3]. DH is 10-20% NaClO, with a 1% stabiliser of sodium hydroxide (NaOH). When used, environmental precautions are mandatory due to the fact this product is extremely hazardous. The presence of PP fibres delays the overall concrete degradation process by lowering permeability, reducing the amount of shrinkage and expansion of concrete [4]. This combination has proved to be a successful material in many types of structures, polymer fibres being used for structural purposes, partially or completely substituting conventional steel reinforcement. PP fibres have numerous properties – low cost, ductility, ease of dispersal and widely considered chemically inert – that make them suitable for incorporation into concrete. However, fibres at the surface are particularly vulnerable due to an intrinsic UV sensitivity. Research has revealed the shortcomings of chemical cleaning using NaClO on polyethersulfone (PES) membranes, detailing substantial effects [5]. However, the corrosive nature of NaOH on PP fibres within concrete is not extensively documented. Research into PP degradation reported that samples lost mass after being exposed to NaOH (2%), the severity of attack increasing as temperature rose and concentration decreased [6].

Studies into polymer fibre scaffolds for tissue engineering applications used NaClO to purposely amend the morphology of the fibres. Higher porosity showed by NaClO-treated fibres indicated that polyvinyl alcohol (PVA) and NaClO acted synergistically as porogens [7]. Other research showed how NaClO caused the oxidation of the hydroxyl groups of PVA, thus facilitating the bio-degradation of the polymer [8]. The exposure of polymers with crystal attachment and growth may lead to a weakening of the bond between materials. Their presence at the cement interface disrupts or distorts the fibre by growth. Despite its widespread use, comparatively limited research has focused on the effects of NaClO on fibre reinforced concrete. None have focused on identifying the mechanisms responsible for the reported effects and no published guidance is available.

METHODOLOGY

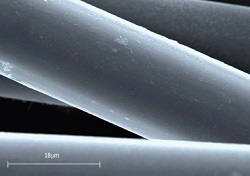

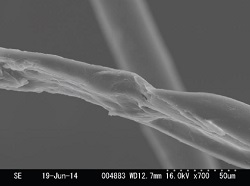

Samples of PP micro-fibres (see Figure 3), circular in section and 18 microns in diameter, were treated with a 2.5% NaClO solution (because the study site operatives use a 20% NaClO solution diluted with water at approximately 1 part water to 1 part NaClO). The macroscopic changes were observed by scanning electron microscopy (SEM), to visualize qualitatively the surface and profile changes along with deteriorations. Characterization by Attenuated Total Reflectance Fourier Transform Infrared (ATR-FTIR) spectroscopy was undertaken to identify the chemical functional groups affected and structural modifications.

Industrial conditions

The PP fibres are exposed to NaClO solution as part of a cleaning procedure to combat bio-fouling on concrete steps. The fibres are used as reinforcement and crack control within marine concrete, forming sea defences in the UK. Many fibres protrude from the surface of the concrete, exposed to power washing, NaClO, NaOH and tidal impact.

Solutions

Two solutions were used throughout the experimental tests. A NaClO solution (2.5%), and a solution of NaCl (3.5%) used as artificial seawater. Fibres were treated ten times to mimic a six month maintenance regime. A treatment consisted of a fibre being covered with 50 ml of NaClO and left in sunlight for two hours. After drying, the fibres were immersed in 50 ml of artificial seawater and left in sunlight for a further two hours. Finally, the samples were washed in water to reveal the surface. This sequence replicated the fibre conditions at the study site, being bleached, dried and then submerged by the ocean.

RESULTS AND DISCUSSION

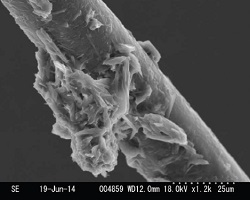

At the time of manufacture, 2005, the study site was the first to utilise synthetic fibres in a marine concrete. Due to the nature of construction of the revetment armour, many synthetic fibres are exposed at the surface of the concrete. The images reported here confirmed the formation of crystals and are representative images of attachment and growth upon synthetic fibres examined from the study site. Symmetrical crystal attachment and growth (see Figure 4) developed on micro-fibres, considerably altering their profiles.

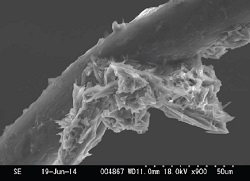

The potential influence of crystals on synthetic fibres used at the site could have a serious effect on the durability of this type of marine concrete which is being promoted beyond the UK, into Europe, Japan and across the USA. Shown in Figure 5 is crystal attachment and growth on the surface of a micro-fibre, giving an irregular shape and increasing the diameter of the fibre by 100%.

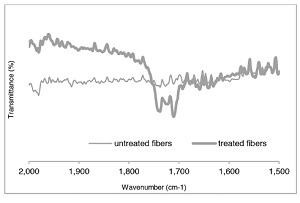

When a chemical reaction takes place there is a change in the chemical structure of a polymer, often causing a change in molecular weight and a loss in physical properties. Chemical analysis by ATR-FTIR demonstrated that treated PP fibres underwent structural alterations. ATR-FTIR spectroscopy of the untreated and treated fibre samples, in the range 4000–600 cm-1 revealed strong bands in the range 2840–2951 cm-1, due to aliphatic C–H stretch, along with strong bands near 1450 and 1376 cm-1, due to bending absorptions of CH2 and CH3 groups, respectively, which are characteristics of PP. The new absorption peaks of the treated fibre compared to the untreated fibre, are shown in Figure 6, revealing the appearance of two new bands in the spectra near 1711 cm-1and 1740 cm-1 of the treated fibres, which is attributable to C=O groups, in agreement with Singh [3]. This indicates the possible creation of aliphatic ketone and/or carboxylic acid moieties after treatment. As a result, the structural and chemical properties of the PP fibre were modified when exposed to an asthenic NaClO solution.

The term ‘inert’ used to describe a substance that is not chemically reactive is often wrongly used to describe PP, and fibre manufacturers, mistakenly, often label their products as having a high resistance to alkali, acid and salt. With PP fibre-reinforced concrete becoming more and more prevalent, the use of aggressive chemicals needs further attention. Guidance is required on the use of such materials and chemicals to enable authorities to make informed choices of appropriate maintenance programmes. The SEM micrograph, Figure 5, shows an interesting irregular morphology, which consists of a protuberant microstructure of irregular-shaped columnar pores with crystalline walls interconnected to each other. The crystal samples studied varied in appearance, with an average size of about 50 μm. EDX analysis indicated that the primary elements were 28.87% Cl (by weight) and 9.98% Na, consistent with NaClO. The occurrence of crystalline structures, particularly attached to fibres (see Figure 5) creates an expansive, damaging, force. This crystallization pressure produces tensile stresses causing disruptive expansion [9]. The effects of this shrinking and swelling, during drying periods and moisture intake, will accelerate the mechanical deterioration process of the fibre bond and cement. Expansion and micro-cracking will also affect the bond between fibre and cement, being a paramount consideration in the design stage.

It can be seen in Figure 7 that crystal attachment and growth has left its mark on the polymer; the fibre surface is deformed, fractured and has developed deep elongated grooves.

The damage is more evident in Figure 8, which shows extensive swelling with the formation of grooves and pits.

This widespread crack and pit formation was also been observed on NaClO-treated PES membranes [10]. The growth of crystals damages the fibres, and after washing of the polymer fibre, degradation clearly appeared. The membranes therefore become more susceptible to water/microbial transport, tidal impact and power washing. Due to the non-polar nature of the PP fibres, and their lower surface free energy, compared to cement paste, a gap is generated between the fibre and the cement matrix [11]. In this void, moisture could permeate around the fibres. Thereafter, following submersion, drying will facilitate disruptive crystals growing at the fibre/cement Interface Transition Zone. As more and more fibres are exposed to hydrodynamic forces (whether tidal impact or power washing) and microbial forces eventual liberation of fibres takes place, leaving many voids within the concrete (see Figure 9). This in turn creates a more porous and algae-susceptible surface and a lack of water tightness. In this situation the fibres having left the matrix do not increase the toughness of the concrete armour as intended, leading to an increase in permeability and paving the way for further deleterious chemical interactions between seawater and cement hydration products (see Figure 10).

Lessons could be learned from other (UK) authorities who purposely do not use such harmful chemicals. The Wyre council, in the area neighbouring the study site, does not use DH combined with power washing, but uses, on revetment steps, a periodic application of an environmentally friendly sprayed biocide treatment. Training should also be considered for the operatives of cleaning machines, bearing in mind alternative procedures which take into account the material and environmental consequences of current unsustainable practices.

CONCLUSIONS

It is the view of the author that we should not use bleach on polymer fibre reinforced concrete. Contour changes were observed by SEM, qualitatively visualizing the surface and profile variations of the samples along with deteriorations and degradation. Characterization by ATR-FTIR identified the chemical functional groups affected. The structural and chemical properties of the PP fibre were modified when exposed to an asthenic NaClO solution. The potential influence of NaClO crystals on the durability of PP fibre reinforced concrete, now widely used across the world, clearly warrants further investigation and research. Based on the findings of this research, regular use of DH on concrete revetment armour steps should be avoided, and further experimental research undertaken to examine the wider use of polymer fibre reinforced concrete and how it is affected by NaClO.

ACKNOWLEDGEMENTS

The author wishes to express his gratitude to Professor Shin-Ichiro Suye at the University of Fukui, Department of Frontier Fibre Technology and Science in Japan. Also to thank Professors Satoshi Fujita and Takenori Satomura for their guidance, and wishes to convey his appreciation to PhD student Ms. Onon Batnyam and Masters student Mr. Arata Kato for their assistance.

REFERENCES

1. Mehta P K and Monteiro P J, Concrete. microstructure, properties, and materials-3rd Edition, McGraw Hill, New York 2006. p 56.

2. Concrete Society, Technical Report No. 65, Guidance on the use of macro-synthetic-fibre-reinforced concrete, The Concrete Society, Camberley 2007.

3. Singh L and Singh R, Swift heavy ion induced modifications in polypropylene. Nuclear Instruments and Methods in Physics Research B, 225, 2004, pp 478-482.

4. Kakooei S, Md. Akil H, Jamshidi M and Rouhi J, The effects of polypropylene fibres on the properties of reinforced concrete structures. Construction and Building Materials, 27, 2012, pp 73-77.

5. Arkhangelsky E, Kuzmenko D and Gitis V, Impact of chemical cleaning on properties and functioning of polyethersulfone membranes. Journal of Membrane Science, 305, 2007, pp 176-184.

6. Baah C A and Baah J I, Polypropylene degradation in NaOH environments, Materials and Design 23, 2002, pp 341-343.

7. Meneghello G, Ainsworth B, De Bank P, Ellis M J and Chaudhuri J, Effect of polyvinyl alcohol and sodium hypochlorite on porosity and mechanical properties of PLGA hollow fibre membrane scaffolds. European Cells and Materials. Vol 16, Suppl. 3, 2008, pp 82.

8. Jayasekara R, Harding I, Bowater I, Lornergen G, Biodegradability of selected range of polymers and polymer blends and standard methods for assessment of biodegradation. Journal of Polymers and the Environment 13 (3), 2005, pp 231-251.

9. Bonen,D, Sarkar S, Replacement of Portlandite by gypsum in the interface zone and cracking related to crystallization pressure, Ceramics Transactions, 37, 1993, pp 49-59.

10. Yadav K, Morison K and Staiger M, Effects of hypochlorite on the surface morphology and mechanical properties of polyethersulfone ultrafiltration membranes, Polymer Degradation and Stability. 94, 2009, pp 1955-1961.

11. Faran J, Introduction: The transition zone –discovery and development, RILEM Technical Report, E and FN Spon, London,1996.

About the author

Dr. Peter Hughes completed his PhD (2014) at the University of Central Lancashire, UK. He has recently started his post-doctoral research at the University of Fukui in Japan. He has written many journal papers and articles on his subject all around the world. His current work investigates the use of polymer fibres in concrete and their effect on long term durability of the matrix. During his PhD studies he was awarded (in 2012) a Japanese Society for the Promotion of Science (JSPS) Fellowship to study at the University of Fukui. He says it was a great honour to be invited back to Japan and continue his work as part of the Frontier Fibre Technology and Science department.