The importance of performance coatings in manufacturing and engineering cannot be overstated, with a direct impact on operational processes, maintenance and environmental obligations. John Bourke, global sales manager at Indestructible Paint, explains why continuous research and development is vital.

From general engineering to aerospace, performance and regulatory objectives are always changing and becoming more stringent, so it is vital that new coating solutions are continually developed.

In many cases, this is most effectively achieved by working closely with customers to produce tailored coating products – often creating solutions that then become part of a standard product range. At Indestructible Paint, some 75% of sales are in response to the defined needs of individual customers, with performance and environmental improvement at the top of the agenda.

In many ways, successful coating development revolves around research and development. By using both established and newly developed testing technology, evaluation can accommodate defined targets over a range of disciplines – such as temperature and abrasion resistance or chemical exposure – using techniques that include the creation of salt-fog and high humidity atmospheres.

For the engineering industry, the results can be seen in many areas, both at the point of equipment specification and commissioning and throughout its maintenance lifetime. The benefits of building a product range, much of which is derived from research and development, are in evidence, from low viscosity and high temperature performance to OMAT repair kits, and thermochromic coatings which change colour under pre-determined operational and environmental conditions.

Most recently, chrome-free products have been in the spotlight, in recognition of the chrome replacement target date for specific products set by the European Chemical Agency (ECHA).

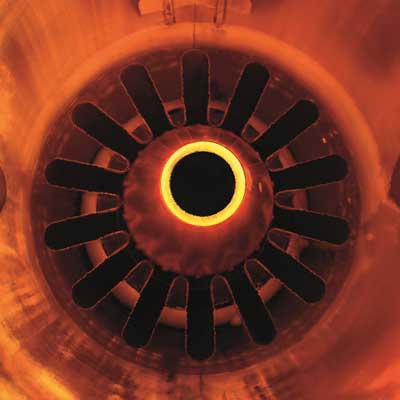

As an example, Indestructible Paint can point towards a new chrome-free diffusion aluminium coating that has been created to offer both performance and environmental gains.

Free from hexavalent chrome at all stages of processing, CFIPAL helps to meet the requirements of the European REACH regulations on the use of chemicals. It is now undergoing detailed, practical evaluation and testing with a focus on high temperature performance alongside stress and crack detection, and is demonstrating excellent stability.

Corrosion protection from dirty fuel and air contamination during operation, while preventing high temperature corrosion and oxidation, are typical of the advantages that can be enjoyed.

The origins of Indestructible Paints in the aerospace industry – a challenging sector that remains high on the list of its markets – have enabled advanced coating technology to be introduced into other areas of manufacturing and engineering, to the benefit of production and maintenance operations alike. When allied to a commitment to research and development, and a willingness to work closely with customers across industry to develop solutions to their coating needs, greater paint and coating performance capability can be realised throughout engineering and industry.

Further information: John Bourke: 0121 702 2485

Email : johnb@indestructible.co.uk

Website : www.indestructible.co.uk