Modular internet of things technology allows manufacturers to bring together previously incompatible data sets to aid condition monitoring and predictive maintenance of critical equipment, says Tony Coghlan, Managing Director, Turck Banner Limited.

Machine vibration is often caused by imbalanced, misaligned, loose, or worn parts. As vibration increases, so can damage to the machine. By monitoring motors for increases in vibration, problems can be detected before they become severe and result in unplanned production stoppages.

However minor performance changes to industrial equipment – including signs of increased vibration – can be difficult to predict without the proper tools. We frequently see modern factories where machines are not as interconnected as would be desirable to meet increasing productivity demands, which are requiring ever greater insight about equipment and operations.

Many manufacturing processes are dependent on legacy equipment, and machines in the same production line can be isolated in multiple ‘automation islands’, often due to different manufacturers or machine builders using different data formats or protocols.

In response to this challenge, the Snap Signal portfolio of modular industrial internet of things (IIoT) hardware and software from Turck Banner was developed to facilitate the collection of valuable data from machines that were never designed with data in mind. This toolkit makes it easy to upgrade a brownfield site and reap the benefits of smart data.

Snap Signal is an overlay network that can capture data signals from virtually any source, allowing previously incompatible device types to become connected. There are currently 20 in-line converters, with M12 connectors, that take various types of signal such as Analogue, Digital, or Thermistor and convert these to smart protocols like IO-Link or Modbus.

These converters are used with splitter cables to connect into the existing control wiring and convert outputs from the existing sensors into a unified protocol, while leaving the existing control system intact, with no requirement for any additional programming or changes.

Following data conversion, the unified signals are then fed back to a variety of Hubs, Masters, Controllers and Gateways to enable the collection, real-time analysis and consumption of the data. Valuable data can now be passed to existing SCADA and Cloud systems, or the Cloud platform provided by Turck Banner.

Snap Signal offers manufacturers the flexibility to monitor key equipment within one area or cover machinery across a whole facility. Down time is kept to an absolute minimum, as the Snap network can be added to a little at a time during periods of inactivity, or during other times of planned maintenance; its modular nature makes it easy to introduce extra sensors for monitoring the condition of critical components.

This provides early warning of failures due to wear and facilitates planned maintenance. Additional sensors can also be added and relocated, without interfering with the normal running of the machine, in order to provide the data for tracking product throughput at different stages in production, therefore identifying bottlenecks, slow downs and short stops.

The ability to relocate these sensors without stopping production greatly simplifies and speeds up the process of identifying the cause of lost production and improves the Overall Equipment Effectiveness (OEE).

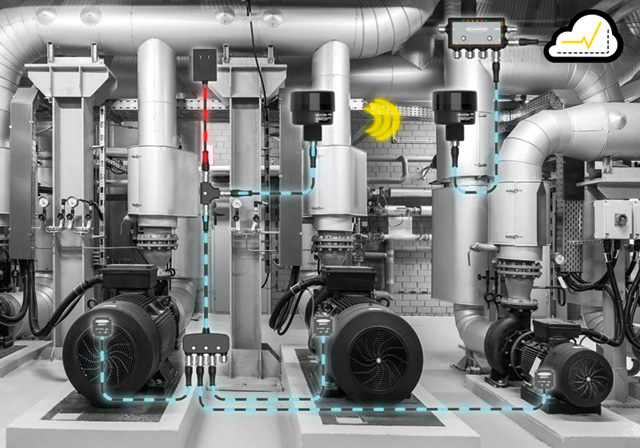

In a vibration monitoring application, Snap Signal allows multiple vibration sensors covering large numbers of motors to be used via a wire consolidation product, such as a four-port splitter or tee.

From there, the sensor data can be connected directly to a controller with edge processing and Cloud capability, or the data can be sent wirelessly to serial data radios. From the Controller, data can be brought to the cloud where dashboards are set up for visualisation, text, and email alerts, to alert personnel to check the motors before they fail.

For companies just starting their journey into OEE, Condition Monitoring and Smart Machines, the toolkit offers an easy place to start learning where the benefits are for them. Its flexibility ensures that nothing will be wasted and a Capex is not needed to start.

Is Snap Signal the Swiss Army Knife of IIOT? While it doesn’t have quite as many blades, it is a lot more useful than a hoof pick tool, and with more converters being added all the time it could prove invaluable.

www.turckbanner.co.uk | enquiries@turckbanner.co.uk | t: +44 (0)1268 578888