Understanding the differences between CIP and FIP gaskets and the advantages and limitations of each will help engineers select the best possible gasket for their application, explains Rebecca Wilmot, Business, Product & Marketing Manager at Permabond Engineering Adhesives Ltd.

In the world of maintenance, repair and engineering, the terms CIP (cure in place) and FIP (form in place) gaskets are often used, and you may be forgiven for assuming that they are one and the same thing, but they are in fact slightly different.

CIP gaskets are applied in a liquid state and cured onto one surface, with the top section of the assembly placed on top of the cured gasket, compressing it to form a seal. The top can be lifted on and off leaving the gasket undamaged, although compression set / bedding may still be an issue. CIP gaskets are often made from UV adhesives, RTV silicones or foaming polyurethanes.

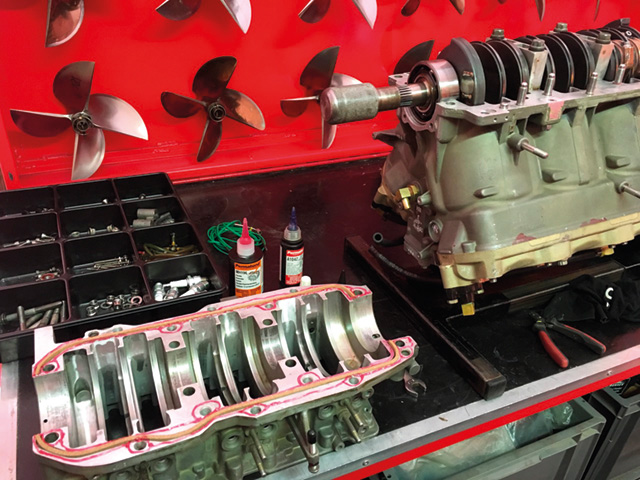

FIP gaskets are also applied in a liquid state. They cure when the parts are assembled and bond to both surfaces forming a seal. Anaerobic adhesives are a popular choice for use as FIP gaskets. They cure in the presence of metal and the absence of oxygen, making them an ideal flange sealant in applications where traditionally a pre-cut / pre-formed gasket may have been used. Dismantling the parts breaks the seal, and if the parts need to be reassembled, fresh adhesive can be applied after thorough cleaning.

Typical FIP / CIP gasket applications

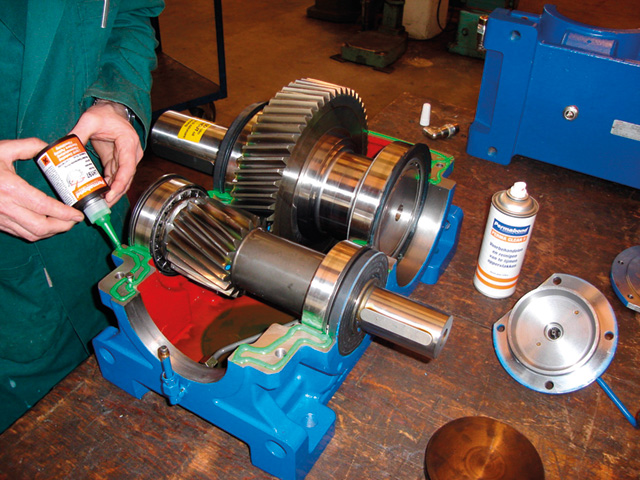

Permabond has been manufacturing FIP anaerobic gasket adhesives for many decades, supplying them throughout heavy industry in metal to metal applications. They are widely used in plant and agricultural equipment for gearbox gaskets, automotive and industrial machinery, for example. They are popular in the automotive industry where silicone gasketing materials are not allowed on production sites.

CIP gaskets can be used on a wide variety of surfaces including plastics. They are often used for sealing electrical housings to give an IP rated seal against moisture and dust. Parts inside the housing may need accessing, to change batteries for example, so their ability to be dismantled and reassembled is advantageous in this type of application. Their environmental resistance tends not to be as good as the FIP anaerobic gaskets, but in these applications there is less requirement to protect against aggressive chemicals or harsh environmental conditions, such as those found in under bonnet applications.

Advantages of liquid, FIP gasket adhesives, over pre-cut / pre-formed gaskets

Permabond’s customers report that the one-solution-fits-all nature of liquid gaskets is a key advantage over pre-cut / preformed gaskets. One adhesive gasket maker can replace a limitless number of pre-formed gaskets of different shapes and sizes, thus simplifying inventory and eliminating delays to servicing caused by having to order special pre-cut gaskets for a specific job. Pre-cut gaskets are also often very fragile, difficult to store and easily damaged. Unlike rubber, wood, paper and cork gaskets, anaerobic FIP gaskets do not perish, shrink or relax over time, eliminating the risk of leaks or particles breaking off and blocking valves.

There is also no “bedding-in” or compression-set with anaerobic FIP gaskets, reducing the need to tighten nuts and bolts periodically. They protect against vibration loosening and can be used to seal any threads and bolt holes, providing 100% seal all round. Pre-cut gaskets do not offer this dual purpose.

What are the limitations of gasketing adhesives?

Anaerobic FIP gasketing adhesives offer excellent thermal resistance of up to 200°C. However, head gaskets and exhaust manifold gaskets may well exceed this temperature so anaerobics may not be the best solution in these applications.

Curing in the presence of metal and the absence or oxygen means that anaerobic gasket adhesives require closely mating metal surfaces in order to cure. If the gap is larger than 0.5mm or substrates are not reactive metals, then the adhesive may not cure.

UV CIP gaskets have less resistance to high temperatures and chemicals. If there are shadow areas that the UV light cannot reach, some of the adhesive may remain uncured.

www.permabond.com | info.europe@permabond.com | t: +44 (0)1962 711661