Powerful leak detection technology is helping to identify fugitive methane emissions from plant, and support maintenance efforts, writes Jason Taylor, Technical Manager and Level 3 NDT (non-destructive testing) subject matter expert at SGS United Kingdom Ltd.

Over the past two years SGS has received a growing number of enquiries for leak detection services, particularly for identifying fugitive release of methane, following a crackdown by the Environment Agency on fugitive emissions. This resulted in the launch of the SGS Leak Detection & Reporting (LDAR) program.

In 2021, at the COP26 summit in Glasgow, the UK Government joined more than 100 other countries in pledging to reduce methane emissions by at least 30% by 2030 as part of the overall aim to secure global net zero by mid-century.

Methane contributes to climate change due to its positive radiative forcing effect and is the second most significant greenhouse gas in the UK after CO2. The major emitting sources in recent years are enteric fermentation, landfilling of wastes, and leakage from the gas distribution system via leaking plant components such as valves, pumps, compressors and flanges.

These emissions can impact the health and safety of workers, contribute to environmental impacts and result in economic losses due to the escaping inventory.

Traditional leak detection methods rely on the fugitive emission passing fixed detectors such as chemical, laser or electrical base sensor technology. These work well in confined spaces where leaks would naturally pass by the detectors, such as bund walls around storage tanks or inside enclosed buildings, however one downside to fixed detectors is that they can miss any leaked vapours in circumstances such as wind blowing the gas away from the detection paths and fixed sensors can never provide full coverage of larger installations.

SGS LDAR services support clients by identifying critical emission sources and assists in creating a focused maintenance program, which can result in significant emission reductions through repair or replacement of leaking components, improvements in safety and reduced environmental impact along with financial savings through reduced loss of inventory.

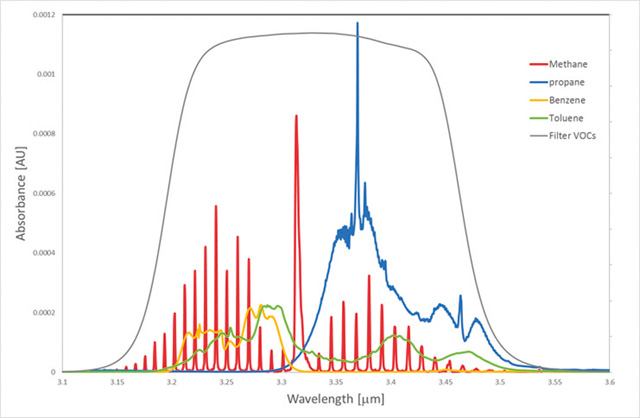

The service utilises the powerful OPGAL camera as the main detection platform which was selected after extensive market research into the options available on the market. This portable device uses infrared imaging technology and bespoke specialist software to effectively identify and quantify the leak from a safe distance and can provide a wide spectrum analysis to identify the actual composition of any fugitive gas cloud.

The GPS enabled camera automatically produces a detailed report which includes an embedded video with full audio, identifying areas of plant and evidence of integrity for the specific area of plant.

A routine check of a site using the SGS LDAR System will detect emissions at much lower levels than most fixed sensors would and can be carried out a safe distance avoiding the operator being exposed to any leak. The system can also survey an entire site in detail, often seeing emissions before they get to the levels that would cause alarm activation on conventional detection methods.

Typically, accepted leak detection levels are often as high as 100,000 ppm which is 100 times that which the SGS LDAR camera can detect and therefore provides a much higher level of assurance that the site is safe. It is worth considering that there will usually be some leakage on an installation, but the owner is responsible for minimising this to an acceptable level.

Early detection and quantification will ensure that maintenance and operations departments can coordinate any remedial actions long before the leak requires an unplanned and costly plant shutdown.

A quantum change in this technology means that it is impervious to background light such as sunny or even very dark overcast days when conventional infrared cameras can miss a gas cloud against the background and make it difficult to be quantified.

Through the use of innovative technology and by partnering with SGS, our clients are able to control of their assets more efficiently, resulting in reduced emissions, improved health and safety and financial benefits.

www.sgs.co.uk/en-gb/sustainability/environment/air-noise-andvibrations-services/field-and-sampling/fugitive-emissions | ukenquiries@sgs.com | t: 0151 350 6666