Businesses must take responsibility for tackling harmful pollution, with greater measurement of emissions set to be critical in this push, says Mark Naples, General Manager, at Umicore Coating Services.

We can’t always see the consequences of air pollution around us. The global economy loses more than $8 trillion annually due to pollution, according to The World Bank. But action to identify its presence and catalogue its makeup and levels still lags.

The problem is that when you visualise air pollution you may think of the great smog of London or a Dickens novel that paints a picture of a blanket of smoke. But just because we can’t see visible clouds of pollution doesn’t mean it isn’t affecting us.

Not only are these harmful pollutants invisible to the human eye, but they are sometimes odourless and tasteless. Yet another layer of difficulty is that they are often found in volatile and inaccessible environments. The most common types of toxic gases found in modern industrial workplaces include ammonia, methane, hydrogen sulfide, chlorine, carbon monoxide, and carbon dioxide.

Thankfully huge advances in sensor technology have unlocked a range of reliable options available for gas detection and the enormous advantages of IR spectroscopy in detecting hydrocarbons and hazardous chemicals are now well established.

Pollution produced by a population of sources

The monitoring of emissions from stationary sources of pollution, such as power stations, manufacturing plants and other industrial facilities, is essential for a whole host of reasons. Not only does it allow the site operator to ascertain the concentration of various gases they are emitting into the atmosphere, but it also enables the relevant authorities to check whether the site is complying with its legal obligations.

Efforts to curb industrial methane emissions – anthropogenic methane is the most potent greenhouse gas on earth – continue to gather pace; its monitoring, detection and mitigation are considered ‘low-hanging fruit’ in our efforts to alter the course of climate change.

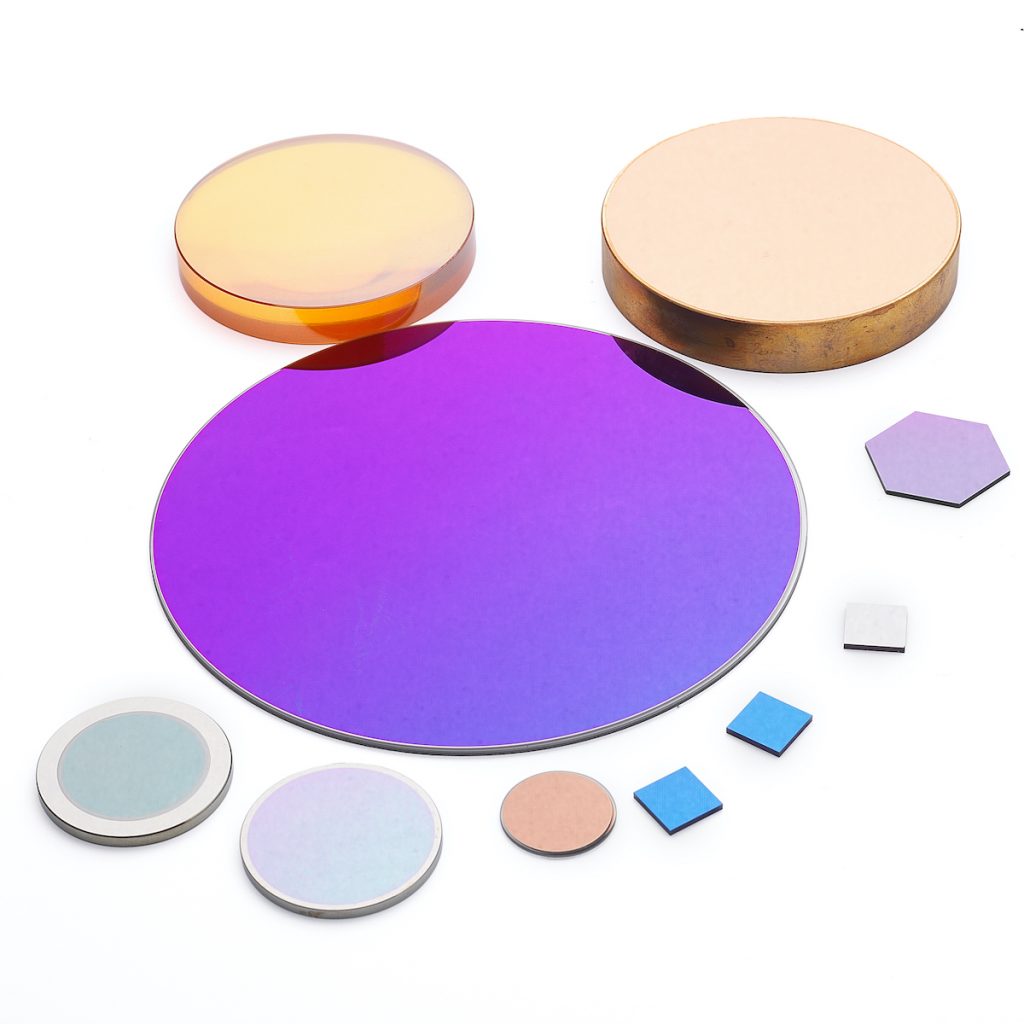

Plant owners who must abide by certain regulatory frameworks therefore invest in measuring equipment so they can report what and how much is coming out of the stack. It is Umicore’s IR gas detection filters, which use an infrared beam to detect and quantify gases present in the atmosphere, that sit at the heart of many of these technologies.

Infrared emitters within the sensor generate beams of IR light.

Having passed through a sampling chamber, a filter in front of the detector blocks out light that is not at the desired wavelength while the detector measures the intensity or attenuation. This is then used to determine the concentration based on the absorption of IR radiation as it passes through a volume of the gas.

Chief among their benefits are the fast response times and accurate results, while not requiring oxygen or external gases to operate. Continuing advances in technology have also resulted in detectors that continuously monitor combustible gases and vapours within the lower explosive limit and provide alarm indications. These can be deployed within oxygen-deficient or enriched areas, require little calibration, and are immune to sensor contamination or corrosion.

Going green and breathing clean

Unless global particulate air pollution is reduced to meet the World Health Organisation’s guidelines, the average person is set to lose 2.2 years of their life. The overwhelming majority of air pollution’s health impact is coming from burning fossil fuels. Among a mix of contributors, transport and industry, and the burning of biomass for cooking, are common culprits.

This is a hyper-local issue and can vary from place to place. It requires a multi-dimensional push, backed by deeper understanding, and that is where data and monitoring come in. For an urgency to be established about cleaning up an area’s air, it must first be considered a problem. Benchmarks must be established; people and businesses must take responsibility.

Similarly, for businesses, it can be incredibly costly to cut pollution. But understanding the idiosyncrasies of current technology and processes will help significantly.

Monitoring and data enable action planning, goal setting, in some cases culpability, and the attraction of funding and research and development. Monitoring can also play into a raised public profile in the press and media.

The issue remains that we need to find ways to make pollution visible as a public health issue. Understanding air quality, wherever that might be, will only help facilitate bright ideas for transport, industry and energy.

eom.umicore.com/en/infrared-solutions | coatingservices@umicore.com | t: : +44 (0) 1382 833022