Britain’s manufacturers are seeing a continued rebound in activity in the second quarter of the year with growth driven by the aerospace and electronics sector, according to a survey from Make UK and accountancy and business advisory firm BDO.

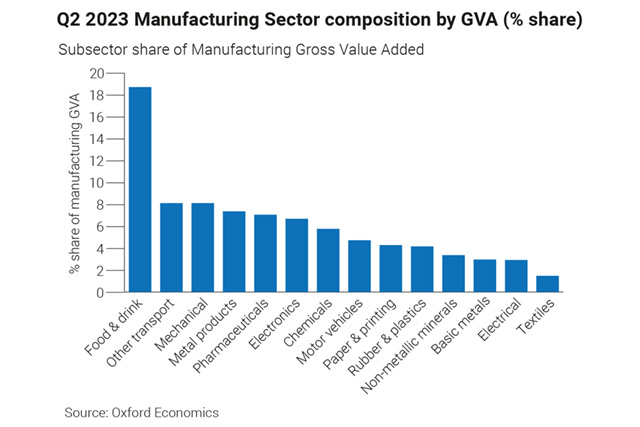

The findings in the Make UK/BDO Q2 Manufacturing Outlook survey show a continued positive picture with the improvement being driven by strong demand in the Other Transport and Electronic sectors in particular, with the balance of output in Other Transport (largely aerospace) extremely strong at +82%.

This is said to reflect continued recovery in aerospace with the increase in passenger miles, together with a spate of large orders for new aircraft over the last year. Strong balances for electronics are becoming embedded as companies invest in digitalisation and extra capacity to counter labour shortages.

These investments are now translating into consistently strong balances for the South East where electronics is the second largest industrial sector in the region.

Make UK is still forecasting a slight contraction for manufacturing in 2023, although the picture remains far better than the significant contraction forecast at the end of last year and in Q1.

James Brougham, Senior Economist at Make UK, said: “Manufacturers are seeing a gradually improving picture but the word ‘gradually’ is doing a lot of heavy lifting. However, companies are at least seeing a relative period of stability after the political and economic turmoil of the last few years when they have spent most of their time firefighting.

“Substantial challenges still remain, however, and so long as there is an absence of an overarching industrial strategy growth prospects will remain anaemic at best.”

Richard Austin, BDO’s National Head of Manufacturing, says the burden on manufacturers still lays heavy, adding: “Despite the first half of the year seeing some pressures easing, there are longer-term systemic challenges in the UK market, with built-in inefficiencies that need to be addressed urgently in order for UK manufacturing to effectively plan and invest.

“Supply chain pressures, for example, are an endemic issue for the businesses we talk to, particularly medium-sized firms. They are facing continued disruption and increased costs, at home and abroad, with many choosing to onshore operations but facing major barriers in doing so. These issues cannot be overlooked by policymakers or we run the risk of tepid-at-best growth for UK manufacturing while neighbouring countries outpace us.”