The use of environmentally harmful refrigerants is being significantly reduced under a 15-year EU phase-down plan

The environmental impact of refrigerants came under intense scrutiny in the 1980s, when the ozone-depleting potential of chlorofluorocarbons (CFCs) became apparent. Since then, a succession of different substances have been adopted in cooling systems.

In 1987 the Montreal Protocol led to the phase-out of CFCs. CFCs were popular as refrigerants because they are non-flammable and inert, but their stability in the atmosphere gave them the potential to add to global warming as well as ozone depletion. Initially they were replaced by hydrochlorofluorocarbons (HCFCs) – these still depleted stratospheric ozone, but to a much lesser extent than CFCs.

HCFCs were less stable in the lower atmosphere, enabling them to break down before reaching the ozone layer. Nevertheless, a significant proportion of the HCFCs still reached the stratosphere and had a greater effect there than predicted. HCFCs in turn gave way to HFCs (hydrofluorocarbons) and PFCs (perfluorocarbons), also known as F-Gases. HFCs are not ozone depleting, but they are still greenhouse gases, with global warming potential thousands of times as much as carbon dioxide.

Global warming potential (GWP) of a substance is expressed as a multiple of that of carbon dioxide. Thus CO2 itself has a GWP of 1. The GWP of refrigerant R404A is 3922 – every kilo of R404A released into the atmosphere has the same greenhouse effect as 3922 kilos of carbon dioxide.

To control emissions from fluorinated greenhouse gases (F-Gases) in industry, the European Union adopted the 2014 EU F-Gas regulation, EU 517/2014, which came into force on 1 January 2015.

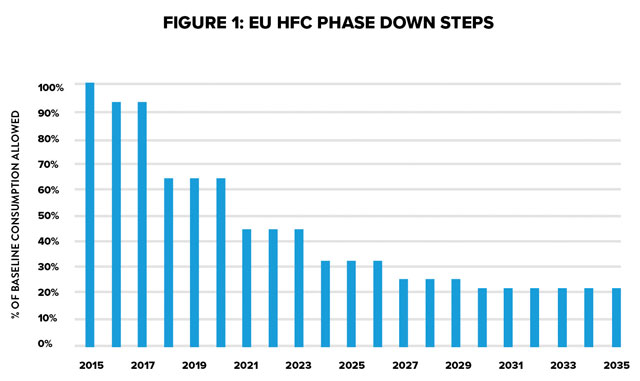

The regulation limits the total amount of the most important F-Gases that can be sold in the EU from 2015 onwards and phases this down in steps to 21% of 2014 sales in 2030, intended to initiate a move towards more climate-friendly technologies. It prevents emissions of F-Gases from existing equipment by requiring checks, proper servicing and recovery of the gases at the end of the equipment’s life.

The phase down is currently at a critical phase, after a large cut in HFC supply in 2018 and another coming in 2021. The phase-down is being achieved by giving producers quotas limiting the quantity of F-Gases they can put on the market, expressed in terms of carbon dioxide equivalent (CO2e). CO2e takes into account both global warming potential and the mass of refrigerant. So 100,000 tonnes CO2e would equate to 25.5 tonnes R404A (GWP 3922) but 70 tonnes R134a (GWP 1430).

The regulations impose other obligations on owners or organisations using refrigerant systems. They must prevent leaks by undertaking leak tests a specified frequency; repair leaks without delay; make sure refrigerants are properly recovered during repair or maintenance and at end of the equipment’s life; and maintain proper records of F-Gas use for every machine.

Leak tests must be undertaken on a regular basis by an F-Gas certified technician from a certified company. The frequency of leak tests is determined by the CO2e of the refrigerant charge and ranges from every 12 months for CO2e between 5 and below 50 tonnes to every three months for CO2e of over 500 tonnes. If a fixed leak detection system is installed, the leak check frequency is halved.

Where a leak is found, it must be repaired “without delay”, or the chiller must be safely decommissioned and the remaining charge recovered.

Equipment with an F-Gas charge in excess of 500 tonnes of CO2e must be fitted with an automatic leak detection system which will sound an alarm in the event of a leak.

Records of leak checks and F-Gas losses and additions must be kept.

The regs are further tightened next January 1 when the use of F-Gases with a GWP of 2500 or more to service or maintain refrigeration equipment with a charge of 40 tonnes of CO2e or more will be prohibited unless the refrigerant is reclaimed or has been recovered during the maintenance of the equipment.

Anyone who undertakes work on equipment containing F-Gases must hold an F-Gas Category 1 certificate. The company which employs the technician must also be certified and listed on a national register.

Given that more climate-friendly alternatives are available for many of the products and equipment in which F-Gases are commonly used (including ammonia, carbon dioxide itself, hydro-fluoro-olefins and HFO/HFC blends), the EU believes its reduction target is achievable at relatively low cost. The legislation is expected to stimulate innovation and green growth by encouraging the use of green technologies based on less climate-harmful alternatives.