New technology including the internet of things will combine to revolutionise the operation and maintenance of burner and boiler applications, says Phil Pett, technical sales manager at EOGB Energy Products.

Burners and boilers play a key role in providing space heating and hot water for industrial buildings, as well as being a critical component of industrial process operations. However, managing their sequencing, while running different operating modes and states, can present complex challenges.

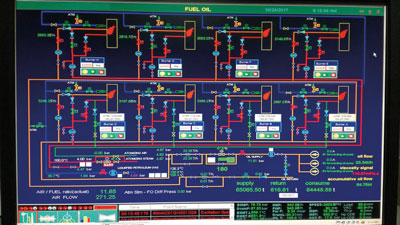

As a result programmable logic controllers (PLCs) are often used to modify the operation of a control system. First introduced in the 1960s, PLCs are used in many heat applications, helping to improve operation and controllability of the burner or boiler system, resulting in lower operating and maintenance costs.

Over the years, with the advances in technology, PLCs have evolved to offer improved features such as greater programming flexibility, smaller sizes and integrated wireless operation. Now, the addition of a range of new technologies is set to transform heating system operation and maintenance.

The heating system of the future

A “heating system of the future” solution will start with the internet of things (IoT) and radio-frequency identification (RFID) technology to collect and track heating system data via a Wi-Fi connection. Augmented reality (AR) will also enhance the management of heating systems.

The IoT allows engineers to see in real time how a burner is operating and, if the system deviates from pre-programmed norms, enables any changes to be made entirely remotely.

RFID is the use of radio waves to identify, track and interact with information stored on a tag. Tags placed on burner plant allow clients or managers on the site to access details of materials, components, spare part numbers and troubleshooting information (such as operation manuals) on a smartphone or tablet.

Augmented reality is the integration of visual graphics over real-world data. In conjunction with RFID, it can be used to identify the components of a burner and superimpose these graphically over a live camera image on a tablet or smartphone. By touching any superimposed graphic, more detailed information can be displayed such as part identification, an interface for ordering replacement parts, process data and service history, and help in maintenance troubleshooting with remote technical support.

Using this technology will allow process data and control commands to be transmitted over the internet, significantly reducing equipment and wiring. It will make functional programming and human interface operation much easier, as engineers can be in a remote location to access secure data on IoT connected devices.

Looking to the future

IoT technology will eliminate many of the system components of a typical PLC control system, with the IoT platform, along with RFID, being used to collect the data and send commands over the internet or intranet.

The combination of these advanced technologies provides a great opportunity for commercial heating systems and applications to improve efficiency, flexibility, reliability and plant safety.

Technologies such as these are set to dramatically change the face of the industry and EOGB is positioning itself at the leading edge of the revolution in the heating sector.

www.eogb.co.ukhttp://www.eogb.co.uk