Emerson’s Gary Ingram explains how augmented reality technology can accelerate the development of less experienced workers and improve efficiency for organisations.

Manufacturing industry organisations are always looking to improve the efficiency of their operations and maximise the productivity of their field technicians. However, with experienced workers retiring and being replaced by a new generation of technicians, maintaining constantly evolving technology can pose problems. It is therefore important for industrial automation suppliers to provide innovative solutions that reduce complexity on the plant floor.

Providing technicians with tools such as augmented reality (AR) to help them in their tasks bridges the skills gap, accelerates worker development, and achieves business value for organisations. To maximise this value and achieve a fast return on investment, augmented reality technology must provide certain core benefits, including improved situational awareness, internet of things data integration, live remote assistance, and knowledge retention to accelerate workforce training.

Improved situational awareness

Field technicians need to know the location of devices and be able to accurately identify the correct assets. But industrial plants can have thousands of devices scattered across vast sites, and similar devices are often next to each other. Using spatial computing technology to visually map plant assets, workers can navigate to the right location faster. As a technician walks around the plant with a mobile device, AR technology overlays digital information – such as real-time analytics, the status of equipment and technical support documentation – on to the physical world. This enables technicians to complete tasks faster and more accurately, reducing downtime and increasing safety.

IoT data integration

AR technology must be integrated with operation technology data systems such as an asset performance platform to maximise its value to operations, but manually engineering that integration can prove costly. To reduce costs, organisations should prioritise solutions with native or built-in integration that simplifies implementation.

Integration enables field workers to receive instant IoT data relevant to a specific asset. Using a mobile device, workers can simply tap an asset to bring up a catalogue of asset and process data, documentation and maintenance history. This enables them to perform faster and more accurate troubleshooting and maintenance.

Live remote assistance

Despite having all the best tools and resources, there can still be occasions when technicians can’t work out what is wrong with a device and they need expert help. However, there is a high demand for experienced technicians and engineers, and waiting for them to travel to the plant can cause delays, as can site access restrictions.

AR provides a more efficient solution in live remote assistance, which enables field technicians to be virtually shadowed by experts, either on site or off. Using AR tools, the experts can see what the field technician sees including live on-screen annotations, and can provide voice and text assistance, and link to additional resources, for safe troubleshooting and repairs. This significantly reduces asset downtime.

Knowledge retention and accelerated workforce training

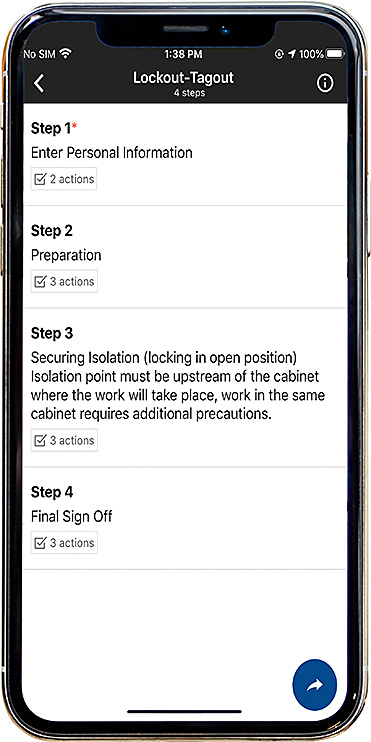

Advanced AR technology enables new or less experienced workers to be trained at a faster rate. Material created during training – such as notes from experienced engineers and step-by-step troubleshooting procedures – can be captured and stored in a dedicated library that can be easily searched and shared for reuse, thereby retaining that knowledge within the organisation. The result is higher quality work with fewer mistakes.

Conclusion

Advanced AR technology can increase the productivity of field workers while reducing costs and repair times. AR solutions improve collaboration, support and knowledge transfer to help technicians work more efficiently and make the right decisions in the field.

AR technology added to Plantweb Optics

Emerson has added AR technology to its Plantweb Optics asset performance platform – part of the Plantweb digital ecosystem of technologies, software and services. Using artificial intelligence, machine learning analytics and data contextualisation, Plantweb Optics provides real-time visibility of plant reliability and operational performance. The addition of AR to Plantweb Optics transforms the way field technicians accomplish complex tasks, through greater situational awareness, live remote assistance, and analytics provided in context of the plant. Unlike standalone AR solutions that require custom engineering, AR is integrated into Plantweb Optics, providing easier and less costly implementation and a faster return on investment.

www.Emerson.com/PlantwebOpticsAR | Tel: 0870 240 1978